|

Mon Jun 23, 2008

18:24

|

|

|

So, nothing terribly exciting lately. The high compression ABA Mk2 has about 600 miles on it since the

engine rebuild/swap, so I'm planning on an oil change tomorrow night. The original radiator was cracking

around one of the upper mounts and seeping coolant, so I replaced that this past weekend. The oil pressure

sensor mounted on the oil filter housing is leaking oil at the electrical connector. I'm also in the process

of finding the best temperature range to use for spark plugs - I have mostly been running a set that are 1

heat range colder than stock. The stock heat range does appear to be a little too warm.

New summer tires came in a while back - a set of Nexen N3000, in 195/45-15. They were crazy cheap, and seem

to grip just fine. I read some reviews which mentioned poor hydroplaning resistance, but it was pouring with

rain today and they seemed to do well. They aren't super quiet, but they're one heck of a lot quieter than

Yokohama A-520s (haha).

|

|

|

|

Mon May 26, 2008

16:38

|

|

|

Can you tell what's different in this picture, other than the front bumper finally being reinstalled?

Last inspection, I was told that I should have side marker lights on my 91 Golf

for the next time. The previous owner had removed them and filled the holes in

the fenders before painting the car. I decided that since anything I did would

require modification to the fenders, I might as well do something cool looking

and unusual. I don't care for the factory A2 side marker lights. I've always

rather liked the A4 style side markers that are also found on some Audis and

Passats - those small, clear, oval ones. So I ordered a pair, along with the

amber colored bulbs, and also scored a pair of the bulb connectors to splice

into my wiring. After that, it was simply a matter of making a template, and

using that template to mark and cut holes in the front fenders - I chose to

locate the new lights in the rear of each fender, just ahead of the front doors

(very similar to their location on the A4s and Audis). With the inner wheel

well linings removed, there was plenty of room to access the lights from the

back. I'm pretty happy with the end result - definitely a huge improvement

over the factory side markers.

Here's one of the 2 spliced adapters to go from the factory wiring harness to the Audi style light:

And here is a closer view of the end result:

|

|

|

|

Sat May 03, 2008

04:25

|

|

|

A quick update: a few nights ago my new alternator arrived and

I installed it. No more charging problems! With everything working

I was finally able to take her out for a spin around the block.

The car had moved under its own power since the engine swap, but

this was the first time I had really driven it. I'm hoping to

get some video footage to post up - watch this space!

|

|

|

|

Sun Apr 27, 2008

14:37

|

|

|

I took a trip to Autozone this weekend, and it turns out that all 3 alternators

are actually bad. Go figure. A new one is on its way. On a related note, I had

tried taking one of the alternators to Pep Boys to have it tested - it took them

10 minutes to discover that they didn't have the right adapter to go from their

machine to the exciter wire terminal. So if you want your A3 alternator tested,

don't waste your time at Pep Boys.

|

|

|

|

Sun Apr 13, 2008

08:01

|

|

|

The major remaining issue with the high compression engine swap is the battery charging

circuit. I've tried 3 different alternators so far, and all produce no output. The

testing procedures in the Bentley manual lead to all 3 alternators being bad... but

I just have a hard time believing that. What I need to do is take the alternators to

an Autozone (free alternator testing!) so that I can be 100% certain. The wiring

is so darn simple with these things, that I'm basically stumped.

On a more positive note, the motor runs great with the Techtonics 268 camshaft

and the ignition timing close to correct. Some of you may be wondering why I chose the

TT 268 over the 270. The 270 has better idle characteristics (close to stock, actually)

and fantastic power gains. The 268 does have a little more lift, but I chose it mostly

for it's large valve overlap period. It is also ground with an offset to favor top-end

power. The larger valve overlap should really favor high compression applications

like mine. Had I kept the factory compression ratio, then I would have chosen the 270.

|

|

|

|

Wed Mar 26, 2008

19:33

|

|

|

So, a little more than a week and a half ago, I started the high compression

ABA engine for the first time. Since I half expected the engine to explode,

I consider this a minor success. Ignition timing issues, alternator issues,

and a clearance problem with the adjustable cam pulley kept me from running

the engine for more than a couple of minutes.

Here are a couple of shots of the new engine, installed, and in a ready-to-run

state:

And here is a close up view of the clearance problem with the Autotech adjustable cam

gear - note the back surface of the gear, where it has "machined" itself against the

edge of the valve cover.

I e-mailed Autotech to see if they had any advice as to whether I should shim the gear,

or clearance the valve cover. I was leaning toward shimming the gear, since the timing

belt was running just a hair over the outside edge of the gear. I never heard back from

Autotech, but in the meantime I ordered a Techtonics 268 camshaft to install at the

same time I addressed the cam gear issue. What I ended up finding was that the Techtonics

camshaft was just a tiny bit longer than the stock camshaft I had been using, and so

the cam gear sat that much further away from the valve cover, which eliminated the

clearance problem. The new cam is now completely installed, and at the same time I

addressed the ignition issue I was having. One of the pins on the ABA distributor body

wasn't completely removed (it was sheared off) and that was limiting the amount of

adjustment I could make to the ignition timing ... I couldn't get it advanced enough

to run right before that pin got in the way.

So, I'm looking forward to starting it up with better ignition timing, and with the more

aggressive camshaft in place.

|

|

|

|

Sun Mar 23, 2008

07:02

|

|

|

I've been meaning to put up a quick post about this for a while now.

I've mentioned it before, but the ABA swap into our Mk2 Golf is using a

complete serpentine belt setup, completely eliminating the original v-belt.

The serpentine setup is far easier when it comes to maintenance, and much

less prone to slipping in wet conditions. For my application, this conversion

was particularly easy, since I'm not using A/C or power steering. This leaves

only the alternator and water pump that need to be driven by the serpentine

belt. The alternator is easy - it can be used exactly as on an A3. The water

pump is a little tricky, because even 4 cylinder A3s have a v-belt to drive the water

pump and power steering pump. I used a fairly common trick, which is to bolt

a VR6 water pump pulley onto my water pump. The VR6 water pumps are driven

from the back side of a serpentine belt, so the pulley is smooth. If you use

this pulley on a 4 cylinder water pump, then you must drive it from the ribbed

side of the serpentine belt - otherwise the water pump will be turning in the

wrong direction. This method works just fine, and you can even get the VR6

pulleys brand new from the dealer as well as most of the online parts stores

(that is, if you can't find one in a junkyard). Next, you'll need to figure

out what length belt to use. For my application, I'm driving the A3 alternator,

water pump with VR6 pulley, and using the non-AC alternator bracket with

automatic spring tensioner. The length of belt I ended up using was 41 inch.

I believe that 40.5 inch might have been a slightly better fit, but 40 inch

was definitely too small. Find a local auto parts store with helpful people

behind the counter, and they'll be happy to help you get your hands on the

different belt sizes.

Here are a couple of pictures showing the new serpentine belt setup. It is

a much cleaner looking configuration than the factory A2 layout.

|

|

|

|

Sat Jan 19, 2008

06:49

|

|

|

Last weekend, the high compression ABA motor became officially installed - the transmission is bolted to it,

and the rear engine mount is connected. With the crankshaft serpentine belt pulley removed from the timing belt

pulley, there was enough room to maneuver the engine so that it would mate up to the transmission. Here she

is, finally home:

While working on the cooling system, I ran into a little bit of a problem. The Mk2 Golf coolant hose which

runs from the front side of the cylinder head down to the water pump did not really fit any more. Two things

that the original engine block did not have were the auto tensioner for the serpentine belt (since it didn't

have a serpentine belt at all) and the assembly for routing crank case vapors. The coolant hose was really

blocked by both of those until I trimmed about a half inch off the end of it. That allowed it fit, albeit

snugly, between the serp tensioner and the lower crank case vent. Most people doing this sort of ABA block

swap would be using a blockoff plate for the crank case vent (like the one Techtonics sells), and that would

save you from this coolant hose problem. Instead of using the blockoff plate, I used the original plastic

vent and simply plugged it using a modified coolant flange plug and o-ring. Here is a picture, showing the

coolant hose wedged snugly between the vent and the serpentine belt tensioner:

|

|

|

|

Tue Dec 18, 2007

19:18

|

|

|

My digital camera stopped working about a month ago, so that has kind of discouraged me from

posting lately. Anyway, here's an update on the high compression ABA engine swap for my Mk2

Golf. The engine is completely assembled, and I opted to use a set of ARP undercut head studs

(they are supposed to be ideal for high compression applications like this) and an Autotech

adjustable cam gear. I removed the old engine, while leaving the transmission in the engine

bay. Once I install the intake manifold, timing belt, and accessory belts, then the motor

can be bolted into place.

Here are some pictures of the new engine, almost ready to go into the engine bay:

|

|

|

|

Thu Aug 09, 2007

18:47

|

|

|

This week I picked up my spare Digifant cylinder head from the machine shop.

This is the cylinder head for my ABA engine swap. I had 50 thousandths of

an inch milled from the gasket surface of the head - when used with the

ABA block, it will give me a compression ratio of 11:1. If this motor

actually holds together, it will be a monster (for an 8 valve, at least).

I'm sure I've mentioned it in one of my very early posts, but the 2.0 ABA

blocks made before the 1996 model year have high quality forged internals

and piston oil squirters. These blocks are perfect for high compression and

forced induction builds. I will start by using the stock camshaft and cam

timing gear, just until the engine gets a few hours on it. With so much

shaved from the head, there will be a 1 degree cam timing error that I really

should compensate for, using an adjustable cam gear. This engine should

also respond pretty well to an aggressive camshaft. I haven't decided which

cam I will use yet. I may try more than one.

Enough yakking. Here are pictures of the head, which has been pressure

tested, milled, and has had the valve seats resurfaced... oh, and check out

my polished combustion chambers:

And here is the head after I spent some time lapping the valves into it:

|

|

|

|

Sun Apr 29, 2007

08:27

|

|

|

Well, the ACN transmission I rebuilt is finally installed in our Mk2 Golf.

While I was removing the old transmission, it fought me every step of the way.

The new transmission went in fairly well, but there were a few hiccoughs along

the way. I guess I'll start at the beginning.

A2 transmission removal is possible without removing the engine, and without

removing the front axles ... but just barely. It is a tight, tight squeeze

and the transmission has to be twisted around into precisely the correct position

before it will drop out from the bottom of the car. First, the starter needs to be

removed (the engine has to be supported first, since the starter bolts are also

the front engine mount bolts - weird, I know), the shift linkage disconnected,

the inner CV joints disconnected, the speedometer cable disconnected, and the clutch

cable disconnected. You can also make the whole unit a couple of pounds lighter

by draining the gear oil first (recommended). I didn't drain the gear oil because

I didn't have room left in any of my oil-draining containers. Next, there are

two 11mm hex bolts that bolt that tin cover plate to the bottom of the transmission

bellhousing. You'll see them at the bottom of the bellhousing, hanging right

below the engine's oil pan on that side. They might be completely invisible

underneath a heavy layer of grime - so grab a brush and start scrubbing if you

can't see them. Other than those, there are only three 19mm bolts left holding

the tranmission to the engine block. Two are near the back-side of the engine -

one up top that goes in from the transmission side, and one down at the bottom

that goes in from the engine side. There is one more on the front-side of

the engine, near the top, that also has a ground strap bolted to it. At

some point you'll want to support the transmission with something (a jack, or

jack stands, or a strong friend).

Next, there are two transmission mounting brackets

(one steel, one aluminum) which both come together to bolt down to a single

transmission mount on the subframe. One bolt holds them down to the mount, and

it's located below the brake master cylinder which makes it kind of tricky to

get to. I used an impact wrench with an impact-grade universal joint and a long

extension (when you use a universal joint with an extension, always try to get

the joint as close to what you're trying to remove as possible - that makes

it a little more stable). The aluminum transmission mount needs to be disconnected

from the transmission. It has some of the shift linkage fixed to it, so you

can either disconnect the linkage from it and remove the aluminum piece altogether,

or you can leave the linkage affixed and just swing the piece up on top of the

transmission (that's what I did, and it didn't seem to be in the way at all).

Anyway, three long bolts hold that aluminum bracket to the differential housing.

I removed two from the top (leaning over the engine bay) and one from underneath

(laying on the ground). You will need to remove the steel mounting bracket

from the transmission also - but it can be tricky. The two bolts holding it in

place go through from the side closest to the body of the car, and even after you

take the nuts off the opposite end, the bolts will not slide out until you let

the transmission drop down so that those bolts can be slid out underneath the driver's

side crumple zone. Then the steel bracket can be removed from the transmission.

Those brackets will both hit the side of the engine bay, preventing you from completely

removing the transmission - so definitely take the time to remove them.

At this point, I had absolutely everything disconnected from the transmission.

There was nothing left holding it in place except for fear and common sense

(as a favorite saying of mine goes). I spent the next 2 hours trying to remove

the transmission from the engine bay. This is where a second person helps -

otherwise it is just a physical wrestling match. The key is to rotate the

gearbox so that the differential is raised up, and then swing the back side

(fifth gear housing side) of the transmission at an angle downard and slightly

toward the front of the car. That sounds easier than it is, trust me. The passenger

side output flange will want to keep catching on the flywheel teeth on the engine,

and the bracket for the front motor mount will want to keep binding against the

transmission housing. Removing that front engine mount completely might make

things easier - and removing the passenger side drive flange from the transmission

would definitely make things easier but could also get pretty messy. I finally

worked the transmission out while supporting it with my knees from under the

car and then let it slide into my lap. The front of the car was jacked up

high enough so that the transmission came out with me as I slid out from underneath

the car. ... and that was Thursday night. I needed a shower and some sleep after

that nonsense.

Friday after work I wrestled the rebuilt transmission into place, which went much

easier than removing the old unit. I had some parts to swap over from the old

transmission onto the new one before installing it, but that didn't take very

long. All in all, it was about 3 hours until the new transmission was physically

bolted into place. I called it a night and cleaned up, counting on getting

all the loose ends tied up in the morning. ... silly human.

Saturday morning I resumed work. Did up the transmission mounts, torqued those

19mm transmission-to-engine bolts, installed the starter (and front engine mount

bolts), attached the shift linkage, and attached the

clutch cable. Before filling the transmission with oil, I wanted to make sure

the clutch felt like it was engaging and disengaging properly. Everything

felt good, so I added 2 quarts of Redline MT90 through the speedometer cable

hole (way easier than using the fill hole on the side of the transmission) and

then attached the speedometer cable. I then turned my attention to reconnecting

the inner CV joints to the differential output flanges. It was about this time

that I realized something major that I had overlooked. The flanges I reused on

the transmission I rebuilt were the wrong size!!! This transmission came out of

an early A2, and used 90mm flanges. My A2, being a 1991, uses the larger

inner CV joints which need 100mm output flanges. I now faced having to swap out

the flanges with the transmission in the car, and filled with brand-new Redline

oil. Crapola. So I bit the bullet and removed the driver side axle completely

(it was the only way to get enough room to operate on that flange), took the 100mm

flange off the old transmission, cleaned it up, then removed the small flange

from the transmission in the car... then I scrambled to install the larger

flange while transmission fluid was peeing out. I didn't want to lose any

more than I had to. That stuff is about $10 a quart (if you find a decent

deal on it). The other side was a little easier because I could just prop the

axle up out of the way rather than completely remove it. In the end I only lost

a few ounces of fluid. That whole operation ate up quite a bit of time, though.

Now I had correct flanges that would mate up to the inner CV joints. I made sure

the transmission was in neutral so that I could rotate the flanges while

installing the inner CV joint bolts... but there was a problem. Even with the

gearbox in neutral, I could not get the output flanges to turn. Before installing

the larger flanges, they turned with little effort. All kinds of terrible thoughts

started to go through my head - had something in the transmission popped loose and

allowed a gear to engage? Had something in the process of installing the larger

flanges caused the differential to bind up? In desperation, I pushed down the

clutch pedal and ran the shift lever through the gears and everything felt fine.

Now everything was mysteriously freed up. Strange. That made me a little

nervous, but everything seemed okay so I continued bolting the inner CV joints

to the transmission drive flanges. With that done, I started the engine with

the front end in the air just to make sure the clutch engaged and disengaged

correctly, and to make sure the tranmsission would actually drive the wheel

hubs when it was in gear. Everything was fine - clutch acted correctly, and

my front brakes started spinning up like crazy as I ran through some of the

gears. Cool. I took this opportunity to install my summer wheels and tires too,

since nice weather is finally here.

So now everything was back together and the car was back on the ground. Ready

for a test drive. One thing that I don't believe I've mentioned yet is that

I rebuilt this transmission using a Peloquin 80% limited slip kit. It takes

the factory 20% limited slip and anti-torque-steer effect and increases it

to 80%. So in theory, it should now take nearly 100 ft lbs of torque for a wheel

to start spinning instead of the factory 25 or so. Anyway, test drive time -

and everything was good. Better than good, actually. The transmission is nice

and quiet (especially compared to my old one, which had some nasty bearing

noise), all the gears engage very nicely, and I'm not leaking transmission oil

from my drive flange seals anymore. That whole thing was a real fight, but

definitely worth it. I need to do an alignment now, though. The alignment was

a little bit out to begin with, and now it's even worse because I had to disconnect

the driver's side ball joint to remove the axle on that side. I may do a writeup

on how to do your own alignment soon. Watch this space.

|

|

|

|

Tue Apr 24, 2007

14:10

|

|

|

As I mentioned in my last post,

I have been rebuilding an ACN code 020 transmission to swap into our Mk2 Golf.

I did not document tearing down this transmission, because my last post documented tearing down an A3

transmission and the procedure is practically identical. Once the unit was disassembled, I was

pleasantly surprised to see that all of the synchros were good, all of the bearings were good, and

there was no damage to any of the gears. The parts for the rebuild consisted almost entirely of

seals and gaskets. Even the large pinion shaft bearing was nice and smooth, with no play whatsoever -

and that is pretty unusual. I think this unit may have been rebuilt in the past, because I'm certain

that it did not come out of a low mileage car (none of our parts cars were low mileage).

Most of the time I put into this unit was in sand blasting (technically, glass bead blasting) the

aluminum case pieces. They came out pretty nice, as you can see here:

The first picture below shows the differential and pinion shaft installed in the case. The second

picture shows the input shaft installed. The third picture shows the 1st through 4th shift forks

installed:

Assembling the two case halves can be tricky if you are not replacing the large input shaft bearing. The

official procedure is to press the bearing into the upper (or rear) case half, and then install the case

halves so that the input shaft presses into the bearing. If you want to reuse your existing bearing then

you would have to pull it off without damaging it first, and that can be tricky. I wanted to reuse the

bearing without pulling it off first, so I tried a trick using the bearing plate to help press the bearing

into the upper case half while assembling the two halves. In the first picture below, you can see the

case halves partially together, which I accomplished by heating up the upper housing with a torch, then

tapping it down onto the bearing (don't pound hard, it could damage the bearing!). I had made sure to

roughly line up the bearing plate before installing the second case half, so that I could then use some

very long metric bolts of the appropriate size and thread to draw the bearing plate up close enough to

be able to install the correct screws (those four inset triple-square screws), which you can see in the

second picture below. That method worked pretty well. The third picture below shows the case halves

assembled and the driven 5th gear in place on the pinion shaft.

Unfortunately, I didn't take a picture of the drive 5th gear (on the input shaft) being installed, but

it really is just the opposite of taking it off. Press it into place (may need some gentle tapping with

a rubber mallet) and get the shift fork back into place so that you can engage both 5th gear and reverse

gear at the same time. You will need to manually move the shift forks to do that, which means you

can't have the selector shaft installed just yet. The first picture below shows the shift forks

through the reverse light switch hole in the selector shaft housing (later transmissions don't have

this hole, FYI) - the fork on each end needs to be pressed down. This will allow you to correctly

torque the hollow input shaft bolt on the end of the drive 5th gear. You may need a friend to help.

Now the selector shaft can be installed. The first picture below shows the selector shaft installed,

with a new seal in place. The second picture shows the installation of the selector shaft cover.

Don't forget that big spring that goes in there. The tool I'm using here is just a bolt with a 27mm

hex head with a couple of nuts jammed against each other. Jamming the nuts probably wouldn't be quite

good enough for removing this plate - welding them onto the bolt would be the way to go. This tool

can also be used for the timing plug in the top of the bell housing.

Now you can adjust the 5th gear shift forks. The first picture below shows me measuring between the

top of the threaded rod and the shift fork. That measurement should be 5mm (or 0.2 inches). In this

picture, I still have some adjusting to do - I am measuring about 0.1 inches.

In the picture below, you can see the 5th gear housing installed. Don't forget to install your throwout

bearing.

Now is also a good time to replace the clutch rod bushing and clutch rod oil seal (actually, the best

time would be just before you install the 5th gear housing). The bushing is very

important - a worn bushing will cause a new seal to start leaking pretty quickly. My bushing was

totally shot. It was worn to the same inside diameter as the rest of the input shaft pushrod bore.

When they get that worn, you cannot push them out from the back like the book recommends without doing

something to plug up that hole first. The easiest way is to get a thread tap that will fit the worn

ID of the bushing and cut threads so you can install a bolt to plug the hole. You can now either

rig up something as a slide-hammer against the bolt you put in, or just whack it out from the back

like the book says to. In the first picture below, you can see the trashed bushing I removed along with the tap I used to

cut the threads. The second picture shows the new bushing about to be installed. Drive it back until

it seats against the smaller inside diamater of the input shaft. The oil seal gets installed in front

of the bushing, sitting back roughly 0.5mm from the end of the shaft.

And here is the end result. I didn't cover the installation of the drive flanges, mainly because I didn't

take pictures of that... but it really is straightforward. If you removed them, you know how to install

them. I installed a Peloquin 80% limited slip upgrade while I was installing these flanges, which

included new flange seals, inner flange caps, brass rings, and good instructions. Well worth the price

at just under $100 (for a kit that does both sides). The stock limited slip is 20%, so it will be

interesting to see what kind of difference I notice.

|

|

|

|

Sat Jan 06, 2007

17:39

|

|

|

Tue Dec 05, 2006

07:59

|

|

|

After I got home from work last night, I pulled the 91 Golf into the garage

and started to attack the exhaust system. The old system was a pain to remove

because it was all welded together. With the old system out, I took a look

at the innards of the catalytic converter and I was surprised to see that it

looked excellent. The previous owner must have installed that cat not long

before I bought the car (it is supposedly a Techtonics high flow cat, but I

haven't verified that yet).

Installation of the new system was problematic at times, but I worked through it.

The diameter of the pipes was so large that everything just barely fit. This

system is supposed to be the same diameter as the stock PF engine'd 8 valve

GTIs. I had no idea any of the factory systems were that beefy. Since I was

installing an exhaust that technically was made to fit a different car (mine is

a Golf GL, RV engine code), I wasn't surprised that I ran into little problems.

The forward-most hanger had to be removed from the body of the car and then rotated

almost 180 degrees. The over axle pipe just barely missed the brake

balance controller (there's about 1/8th inch of clearance). The intermediate

pipe rests firmly on the rear subframe, and there is absolutely no adjustment

in the system to raise it. It's so close to everything everywhere that once

everything physically fit, there was no adjustment for anything. My rear-most

hanger was missing (since the last system didn't use it), so I had to make a

hanger to mount to the stud coming out of the body. The other issue I ran into

was with some of the hardware that Bosal provided with the system. I nearly

stripped out 2 of those nice copper nuts because they got cross threaded... and

I was trying to be incredibly careful for that very reason. I had to chase the

threads out with a tap in order to use those nuts, but that destroyed the nuts'

self locking ability. Bummer.

With everything installed, I started the engine to make sure there were no leaks

and to see how bad the rattles would be. Amazingly, the system does not rattle

at all. Some vibrations come through the body because one of the pipes is resting

on the rear subframe, though. I will insulate that with some rubber, I think.

The system is quieter than I expected, but the rear muffler appears to be glass

packed which means the sound will change as it gets broken in.

|

|

|

|

Mon Dec 04, 2006

12:47

|

|

|

Last Thursday I finally got pulled over for the exhaust on the 91 Golf.

I was only pulled over for a couple of minutes, and I didn't even get a

written warning so it may have just been a "drunk check", so to speak.

Anyhow, that got me thinking that I should start looking at new cat-back

systems for it. I've been real lucky not to have been pulled over at

all until now.

First off, I figured I should get a new catalytic converter at the same

time. The Golf used to burn a lot of oil (before I replaced the valve

stem seals) so the cat may have some clogging. In addition to that,

the previous owner had the mid-pipe welded to the catalytic converter.

Between those 2 things, I can't count 100% on being able to reuse the

existing cat. To top it off, I thought it would be nice to upgrade to

a 55mm cat, which was the largest that they used on any A2 Golf/Jetta

from the factory. I found a new OEM (Emico) cat at autohausaz.com for just over $150,

which is a pretty good deal. The 55mm cats were used on, among others,

the later 8 valve GTIs with the PF engine - so I kept that in mind while

looking for parts (mine is a Golf GL with the RV engine, at the moment).

Even though I wanted a stainless cat-back system, I didn't want to spend

the money for one (for the most part, they were $500 and up). I saw

that the Bosal stainless sport systems were not necessarily made entirely

of stainless steel (their description says all mufflers and "select systems",

whatever that means, are stainless), and I didn't want to spend almost $400

for a system that might end up being partly aluminized instead of

stainless. I did some more price checking online, and even priced out

a completely factory system (Ansa/Bosal) - which was looking like the

least amount of money. A factory system would have been a little too tame

for my taste, but I was considering it.

The next day I headed to

Atlantic to see what they could do for me, since I know they're good

about trying to match online prices. I won't disclose what I ended up

getting for a deal, but I was pleasantly surprised. They said they were

pretty certain that the Bosal sport stainless systems for the A2s were

made entirely of stainless, and then they quoted me a fantastic price

for one of the systems. To make a long story short (too late?) I ended

up with the cat and a stainless cat-back system for only a little more than

I would have paid online for a cat plus a nice aluminized system.

I went to pick up the system today, and was thrilled to see that it was not

only made entirely of stainless, but it was also completely polished and

used flanged connections! In this picture, you can see the whole system

laid out, along with the new 55mm cat:

|

|

|

|

Wed Nov 15, 2006

18:53

|

|

|

Older VWs like to keep you busy, and my Digifant Golf has been no

exception lately. I posted some time ago about replacing the knock

sensor, and she just ran fantastic after that... for about a week.

The next gremlin was a cold starting issue that got so bad I nearly

gave up on getting the car started after work one day. The car

would run fine after warming up, but would run rough for the first

minute or so after a cold start (if it even started, that is).

In the process of troubleshooting, I tested the fuel pressure by

hooking up a fuel pressure guage to the fitting on the end of the

factory fuel rail. The pressure was 44 psi - quite a bit higher

than it should have been, which indicates a bad fuel pressure regulator.

I replaced the fuel pressure regulator (pretty easy chore, it's

quite accessible), but it was not related to my cold starting issue.

I eventually had it narrowed down to either the coolant temperature

sensor or the ECU itself. The ECU uses the signal from the coolant

temperature sensor to determine how far to advance the ignition timing

under certain conditions, so it's pretty critical that the sensor

operates correctly. I really didn't suspect the coolant temperature

sensor because I had replaced it a couple summers ago, but when

I tested it I found the signal was way out of whack when the coolant

temperature was cold. As the coolant warmed up, the signal from the

sensor quickly pulled back into it's correct range. The sensor is

an easy and inexpensive fix, so I was happy. With the sensor

replaced, my cold start issues were gone and the Golf ran real nice

immediately after cold starts - no more rough running.

With the Golf really straightened out, I thought it would be a good

time to install a Digifast 2 performance chip from vw_pilot (if

you're on the vortex, look him up if you need a digifant 2 chip).

It was $42 including shipping; however, I never received it. After about

a month it was looking like the post office had just lost it or

something. The seller was great about it, though - he sent out

another one, at no charge, via usps priority mail so we could track

it. The chip arrived this evening, so I installed it and took the

Golf for a quick test drive. I am definitely happy with it. There's

some extra pull at low RPMs under heavy load. I didn't really wind

it out, so I have no idea how it affected the top end under full

throttle yet. My favorite thing about it, though, is the fuel

cutoff when the throttle closes. The fuel shuts off completely when

you let off the throttle, until the RPMs reach idle speed. That

may not sound like anything, but it's a huge difference in "fun

factor" as it really increases the engine braking. The Digifant II

cars are fairly high compression (high enough so that they use a knock

sensing system), so there's some pretty decent engine braking when

the fuel is cut off. Not only that, the RPMs drop quicker between

shifts, which means you can shift that much quicker without trashing

your syncros. In fact, the RPMs drop so quick that most of the time

I end up double clutching when up-shifting in order to bring the

RPMs back up to where they should be for the next gear.

Here are pics of the new chip - one before installation, and one

after installation (click for larger view):

|

|

|

|

Sun Oct 08, 2006

18:09

|

|

|

It's now been a few days since the FK 60/40 springs have replaced my old, trashed

Tokico springs and I'm still very happy with them. Even though the front springs

are lower and the rear springs are the same height, the FKs provide a better ride

while still keeping my tires from rubbing against the fenders (with the Tokicos,

I had to be very very careful - even small bumps would cause the rear tires to

rub). Fortunately, the Tokico dampeners are much better quality than the Tokico

springs, and they work well with the FKs. The front dampeners should be changed,

though, because the Tokicos have too much travel (which means the springs are

loose, just flopping around, when the vehicle is raised off the ground). A set

of Bilsteins in the front would be really nice, but they're pricey.

My Golf, with Tokico HP shocks and FK 60/40 springs:

|

|

|

|

Wed Oct 04, 2006

17:22

|

|

|

*sigh* Is anyone out there thinking about purchasing Tokico springs for their

Volkswagen? If so, then take my advice and don't spend money on them. A year

ago I installed a Tokico HP kit, which consisted of dampeners (struts) and

springs. I was pretty happy with them at first, but that didn't last very long.

It was only a matter of months before the handling started to get worse, and

the front end started making all kinds of horrible sounding groans and clunks.

Some time ago, I got under the car to find out what was going on, and there was

nothing obviously wrong - everything felt real tight. I did notice, though,

that the springs were looking incredibly poor. Yes, in almost exactly one year

the Tokico HP springs had degraded to the point that I could only describe them

as "beat". I saved about $100 over the cost of a quality suspension setup from

H&R, and about $300 over the cost of Bilstein struts with Neuspeed springs...

and now I wish I had spent the extra money because the Tokicos are complete junk.

The dampeners are still working fine, thankfully.

What I decided to do this evening was remove the Tokico springs and replace them

with a set of FK 60/40 springs that I had hanging around. FKs are some of

the best springs out there, but FK products can be a little bit difficult to

get in the U.S. I scored a set a couple years ago, though - behold: (click

image for larger view)

I only had enough time to do the 2 front springs tonight, I will do the rears

later. The front FK springs are 60mm lower than stock, which is even lower than

the Tokicos I had been using. Both the Tokicos and FKs are so short that I

didn't have to use spring compressors to disassemble and reassemble the struts.

Here are a couple of pictures of the Tokico springs that I removed (click them

for larger versions):

I took the Golf for a quick spin, and the difference is amazing. Even though the

FK springs are shorter and stiffer, the ride quality is much, much better and there

are no more funny groans and clunks when I go over bumps or cut the steering

wheel at low speeds.

If you're going to spend your hard-earned money, spend it on quality.

|

|

|

|

Tue Sep 26, 2006

18:27

|

|

|

My 91 Golf is well on it's way to running really nice (new oxygen sensor, and new knock sensor on the way).

While I was searching for Digifant II troubleshooting info (even though I have the Bentley book, I still

like to search the web), I found a guy who sells reprogrammed Digifant II chips. There are a few choices

out there when it comes to Digifant II chip upgrades, but some of them ignore knock sensor input, which

requires you to run high octane fuel all the time. One of the most well known upgrades is the Autotech

chip, which also comes with an aluminum bushing to mount between the knock sensor and the engine block -

that basically dampens the feedback through the knock sensor, which I'm not crazy about. To me,

if the knock sensor and ECU are working correctly, and if the engine itself is in decent mechanical

shape, then there's no reason to alter the factory knock sensor setup. I'd rather keep that functionality

100% intact if possible. This other chip I just found out about not only preserves the knock sensing

system, but actually samples input from the knock sensor (as well as several other sensors) more

frequently than the stock program. The chip gets great feedback from other folks who have used them

(there is an entire thread on VWVortex dedicated to praise of this chip upgrade), and seems to be more

of a driveability upgrade than a performance upgrade. Well, the chip upgrade is only $42 including

shipping, so I went ahead and ordered one. I will put up a post once I receive it and install it. These

chips only work with certain Digifant II ECUs - luckily, I have a KEN box which is original (as opposed

to the later boxes issued around 1996 which supercede the original ones). Siemens, Triumph-Adler, and

Bosch also made original Digifant II units.

|

|

|

|

Thu Aug 17, 2006

17:40

|

|

|

So, part of the reason I haven't posted since our trip to Great Britain is that

I've been having exhaust issues on my 91 Golf. The system, as you may know,

is a Brospeed (Bosal) header

into a

Techtonics high flow catalytic converter and then straight pipe to a single

Flowmaster Delta Flow

muffler. Let's just say it has plenty of "character" (that means it's loud). Ever since I finished the

shift linkage rebuild, there has been a little bit of a leak between the header and

the catalytic converter. It wasn't much of a leak, but just enough so that I noticed

it. The part that was sealing that join was nothing more than a strip of stainless steel

mesh wrapped around on itself to form a ring. A couple weeks ago I decided to drop

the exhaust again and get that sealing ring seated a little better. To make a long story

short, I disassembled and reassembled the exhaust 5 or 6 times over the next couple weeks

and only managed to make the leak even worse. Along the way, I tried several different

parts to replace the strip of mesh that was on it. I tried a ring from a Jeep Cherokee

downpipe, but that was too small. I tried two different factory VW exhaust rings, and

both of those were too big (in fact, they appeared to be identical even though they were

different part numbers). Finally, I got in touch with the good people at

Bosal North America and they sent

out the correct part to fit their header. I figured that was the best way to get something

that was going to fit correctly. Even if I had managed to find a universal part with the

correct inner and outer diameters, I really wasn't sure how deep (thick) the ring needed

to be in order to seal properly. Well, the part from Bosal arrived today and I just finished

installing it this evening. No more exhaust leak!

I'm now surfing the web, looking for good prices on cat back exhaust systems. My cat-back system

is just too loud for this quiet little neighborhood we moved into, and it's getting kind of

tender anyway. I can get an entire Ansa cat-back system, but it's a factory replacement system

and isn't likely to have much of a sound at all. Our 95 Jetta has the Ansa factory replacement

cat-back system, and it sounds great for a stock system but it's just far too civilized for an

A2 GTI clone like mine. I need something with a little bit of a bark. I would be thrilled to

find something that sounds as nice as the stainless Neuspeed exhaust on Claire's 96 Golf, but

I doubt that's going to be the case with the cheaper systems that I'm looking at.

|

|

|

|

Sat Apr 15, 2006

20:19

|

|

|

Last season I ordered a

MissingLinkZ solid shift kit

(an all metal shift linkage with spherical rod ends) along with MissingLinkZ teflon bushings for the relay shaft,

UHMW poly selector "ball" and teflon poly bushing for the main shift rod. I also ordered a factory "rebuild kit"

for the lower end of the shift lever. Soon after receiving the parts (which turned

out to be pretty nice quality), I installed everything except for the bushing for the main shift rod (the rod

that goes from the gear shift lever up into the engine bay) and the shift lever rebuild kit. To install those

parts on my A2 requires the exhaust system to be disconnected and dropped, the exhaust heat shield to be removed,

and the shifter box/lever/rod (the whole linkage from the passenger compartment to the engine compartment) to be

removed. I wanted to wait until I had a replacement part for my reverse gear lock-out so that I could do that at

the same time. It's a plastic piece pop-riveted the shifter "box" that is much easier to drill out and remove

with the box removed from the car.

So this weekend I decided it was finally time to replace that bushing, install the shift lever rebuild kit, and

fix my reverse gear lock-out. I worked at a pretty leisurely pace all day Friday (had the day off from work)

and then finished bolting the exhaust back up this morning (Saturday, that is).

Here is a shot of the engine bay, in which you can see some of the MissingLinkZ kit - especially that nice billet

weighted shift rod painted with silver Hammerite. The kit is

great, and made a huge difference in the feel of the shift linkage - no more A2 slop! This kit is nice because

it eliminates rubber bushings in the factory linkage by using all metal spherical rod ends instead.

Here is a shot of the exhaust disconnected between the catalytic converter and header, and the heat shield

removed. To get my exhaust to drop down far enough, I had to disconnect all the hangers. Even then, the heat

shield was tricky to get out without damaging it

With the heat shield removed, you can see the bottom of the shift box and the main shift rod coming out of it:

Four bolts hold the shift box to the body of the car - when you remove them, the whole box will drop down:

At the other end of the main shift rod, just going up into the engine compartment, there is a clamp arrangement

that provides adjustment and fixes the main shift rod to the rest of the shift linkage. In all factory A2 Golf/Jetta shift

linkages (except for 1992 and some 1991 - they have additional adjustment) this is the only point of adjustment - you can adjust both side-to-side

and front-to-back throw of the shift lever. Here is a shot showing the clamp arrangement and the single bolt that

hold it in place. Remove the bolt completely and the sleeve clamp will slide off the end.

With the shift box disconnected and the main shift rod unclamped, the struggle to remove the whole assembly can begin.

Most of the work is trying to squeeze the shift box down past the exhaust. Don't forget that the shift lever is still

sticking way up out of the top of it, so that really makes it awkward to remove. If you can work your exhaust all the

way to the side, then it won't be as bad. My exhaust, however, barely moved aside enough to get the box dropped

down.

With that whole mess of shift box, main shift rod, and gearshift lever removed from the car, my next job was to

remove the gearshift lever from that whole assembly. There are two small nuts holding the shifter base to the

shift box and once those are removed the whole shift lever can be worked free. Kind of tricky because you have to sort of muscle it out

while sliding the main shift rod back at as extreme an angle as possible. It's hard to describe, but pretty obvious

once you have everything out where you can see it. Carry on sliding the shift rod back to remove it from the shift

box. I removed it completely so I could clean up the box and the bushing mounted in it. You'll want to replace that

if if it's worn, brittle, or broken. Here is my shift box with the shift lever and main shift rod removed:

In the picture above you can see the white piece of plastic pop-riveted to the shift box - that's my old, broken

reverse lock-out. You can just barely see part of the shifter base in the bottom of the box - it's a plastic and

rubber piece that simply presses into the bottom of the box and acts as a seat for the mating part of the shifter

base (a plastic ball on the bottom of the lever). My rebuild kit for the shifter base included this piece, so I

removed the old piece just by working it out from the bottom. The new piece slid in from the top quite easily.

And here is my shift lever with the replacement shifter base ball installed - the ball is the mating part for that

piece pressed into the bottom of the box that I mentioned above. The ball is spring loaded so to remove it you

have to keep it pressed "upward" (toward the top of the lever) and drive the roll pin out of the bottom of the lever

and then the ball will slide right off the end.

Here is a side-by-side comparison of my old, broken reverse lock-out piece and the replacement piece that I found

from another car. You can see that the piece on the left is complete and has a tab to keep the shift lever from

engaging reverse unless the lever is pressed down. The piece on the right, obviously, has had the tab broken off.

This is common for older VWs and will make it difficult to get into first gear and possibly even cause you to

shift into reverse without realizing it. To remove the old piece, just drill the heads off the rivets (the rivets

in mine were copper).

You can pop-rivet the new piece back into place like I did, or you can use short bolts and

nuts. If you use bolts, install them so the heads of the bolts are on the inside of the shift box and you

may even have to grind the heads down so they don't stick out as far. Otherwise they may interfere with the shift

lever's movement. I prefer rivets for this because the head ends up nice and flush rather than sticking out.

Here is my shift box with the replacement piece riveted into place:

The last part of my chore was to remove the bracket for the relay shaft which mounts to the top of the steering rack.

The main shift rod passes through a bushing in this bracket, and it's that bushing I needed to replace with the new

teflon part. There are three bolts that hold this bracket to the steering rack. The two in the back you'll have to get

from under the car, and having the exhaust system and main shift rod out of the way first really helps get to them.

The third bolt is trickier (in fact, it's even tricky to locate at first) and I could only get to it by leaning over

the engine bay and reaching down to it with a long extension on my ratchet. The bushing is held in place by a metal

shell pop-riveted over it and if you were replacing it with a factory-like rubber bushing then you could just slide

the old one out and slide the new one in. My replacement teflon bushing, though, was rock solid so it could not

squeeze into place like that. These MissingLinkZ shift rod bearings come with two short bolts and nylon-insert nuts

because of this. I had to drill out the rivets, swap the bushings, then use those bolts and nuts in place of the pop

rivets. I could have pop-riveted it back together, but the bushing came with those nuts and bolts so I decided to

put them to use. Here is a picture of the relay shaft bracket with the new teflon bushing sitting loosely in place.

Next to the bracket is the metal shell that holds the bushing in place:

From there on, it was a matter of putting everything back together. Reinstalling the relay shaft bracket, installing the

shift lever and main shift rod back into the shift box, then working the shift box back into place while routing the

main shift rod back through the relay shaft bracket, and then reinstalling the heat shield and putting the exhaust

back into place. The shift lever base rebuild kit and teflon main shift rod bearing made quite a difference in the

feel. Gear selection is firm, positive, and smooth. As close to perfect as you'll ever get in an A2, methinks. And having

a working reverse lock-out is just great - that alone is worth all the work involved.

|

|

|

|

Thu Jan 05, 2006

20:16

|

|

|

I know it's been a while since my last post, but that doesn't mean nothing's been happening!

I've got plenty of stuff to share, but this post is just for my most recent car-related

activity. I've known my A2 Golf needed a new head gasket for some time now, so I finally

got around to doing it. This past weekend was a good time for it, since I had Friday and Monday

off from work. Saturday I started to come down with some kind of bug - I felt pretty run down

and had a sore throat. I made it a lot worse by spending all day Sunday and all day Monday

out in the freezing cold New England winter tearing my car apart and putting it back together.

So what are the symptoms of a headgasket leak? Well, it can vary quite a bit. The main

components of an engine are the engine block and one or more cylinder heads. An in-line

engine will have one cylinder head, while most boxer and "V" engines have 2 cylinder heads. One

exception to that is Volkswagen's narrow angle V6 (VR6, as they call it) which has only one

cylinder head. The engine has passageways for circulating oil and coolant, and these passageways

run through both the cylinder head(s) and the block. The head gasket goes in between the block

and the cylinder head, and provides a seal to keep these oil and coolant passageways from leaking

into each other and into the combustion chambers. The gasket also keeps coolant and oil from

leaking outside of the engine. So depending on where the headgasket is leaking,

the symptoms could be oil and coolant mixing with each other (there will be oil blobs floating

in the coolant reservoir, and coolant sitting in the bottom of the oil pan), or coolant leaking

into the combustion chamber(s) and getting burned, or oil leaking into the combustion chamber(s)

and getting burned, or coolant and/or oil leaking to the outside, and running down the engine

block. In some cases, a headgasket failure can cause compression from one cylinder to leak

into a neighboring cylinder, which can really screw up the way the engine runs.

Here is the subject: 1991 Golf, 1800cc 8 valve, Digifant II.

Here's the dirty, old engine bay.

The easiest way to drain the coolant on this car is to disconnect the lower hose going to the

water pump. If you don't drain the coolant, you'll get a huge mess when removing the

cylinder head. I didn't drain the oil, because the level doesn't come up past the top of the

block.

Here the valve cover has been removed, and you can see the splash guard that sits directly

over the camshaft. That white stuff on the splash guard is a sign that there is a *lot*

of moisture getting mixed with the oil. This could indicate a bad head gasket.

Yikes! This is the under-side of the valve cover. Lots more of that white goop. It is

normal for some of this stuff to develop, especially if the car gets driven mostly for short

distances or if regular oil changes aren't performed. This much of it, however, is not

normal.

The "goop" has the consistency of warm peanut butter, and even though it looks nearly white

in these pictures it's actually a light brown (not quite as dark as peanut butter, but

close).

Here is a shot of the engine block all by itself in the car - the cylinder head has

been removed. This car has a Brospeed header installed, which turned out to make things

a little difficult. One of the pipes in the header just barely blocked one of the intake

manifold bolts from coming all the way out. Unfortunate, because the best way to get access

to the exhaust manifold/header nuts is to remove the intake manifold. In the end, I elected

to disconnect the header from the catalytic converter, and remove the cylinder head with

the header and the intake manifold still attached. It was very heavy that way, but it

worked out well.

Here's the grimy, old head gasket. Some of the coolant passageways were completely blocked

with crud.

This is the cylinder head, removed from the engine bay with the header and intake manifold

still attached. Lots of carbon buildup in those combustion chambers.

Here is the underside of the cylinder head again, after I spent a few minutes cleaning up

and blocking the surface that mates against the gasket. I used a good, heavy straight-edge

with some fine sand paper and diesel fuel to wet sand the surface (using the straight-edge

as a block for the sand paper).

Here is the gasket surface of the block after getting the same treatment. I also spent

some time cleaning some of the nasty carbon build-up from the tops of the pistons.

Hooray! The cylinder head is now back in place and bolted down. Some head bolts are

made to stretch when they are torqued down, so they cannot be re-used. Others are

not made to stretch, and can be safely re-used as long as they are not damaged.

Here's everything else installed - looks nearly the same as when we started! After refilling

the coolant system, I tried to start the car... and no luck. It just kept cranking. By this

time it was really late Monday night, and I was really feeling under the weather and I was

sick of being out in the cold. So I gave up for the night. I finally got a chance to look

at it again tonight, and it just turned out to be the valvetrain timing. Once that was corrected,

she fired right up.

|

|

|

|

Sun Sep 25, 2005

18:24

|

|

|

Here are pics of the block, with all 4 pistons/conrods installed:

Here is one of the reasons that the OBD-I ABA block is such a

popular upgrade - they have 4 of these piston oil squirters

(normally only found in high end turbo applications) from the factory:

Here are some shots of the valve spring compressor that my dad

and I made:

It works well. In the pictures above, you see it bolted to the

cylinder head that I will be using on top of the ABA block. There

are no valve springs or valves in the cylinder head in the pictures -

these are just to show the way it works. That little window cut

into the "foot" of the spring compressor allows access to the

valve keepers once the springs are compressed.

Here is a box full of the valves, valve springs, keepers, and

retainers that will be going into the cylinder head. They

are all stock.

|

|

|

|

Sat Sep 24, 2005

19:29

|

|

|

A quick update for tonight - all 4 pistons/connecting rods are now

installed. After mis-reading the markings on the connecting rods and the

rod bearing caps, I had all 4 caps installed wrong. Once that was

corrected, everything turned over nicely.

I found the camera, so tomorrow you can see pics of the home-made

valve spring compressor that I will be using for the cylinder head

that will be going on top of the ABA block. It should work well, I think.

|

|

|

|

Thu Sep 22, 2005

17:20

|

|

|

I can't find my camera, so I don't have any pictures to post with this, but

3 of the 4 ABA pistons are now installed. "Why only 3?", you ask? Well,

there was an incident several days ago. I accidentally broke a couple

of rings while attempting to install the first piston. My first attempt was

using a rolled piece of sheetmetal and a couple of hose clamps to compress

the rings. That arrangement was awkward to work with - nearly impossible

to get the bottom edge of the sheetmetal to sit perfectly flush against

the top of the cylinder block. That meant that there was a little bit

of a gap between the ring compressor and the block that allowed the rings

to expand just enough to get all mangled as I drove the piston into the

block.

The day after breaking the rings, I ordered replacements. Just last night

I found that my dad had borrowed a real ring compressor from a friend of

his. So we tried it out and had great luck getting 3 of the pistons

installed. The new rings arrived today, so now I can get the fourth one

out of the way. Pics when I remember where my camera is.

|

|

|

|

Wed Sep 07, 2005

18:15

|

|

|

Yesterday I called Atlantic and had them order a set

of correct piston rings for my ABA build. They arrived today, so I went and picked them up.

These are Goetze instead of Mahle. Both are superb quality, but at least the instruction

sheet with the Goetze rings has better grammar.

I was planning on getting the crankshaft and pistons/rods installed tonight, so I started by

opening my package of new main bearings:

That little white packet contains the 4 thrust bearings that get installed on either side of

the #3 main crankshaft journal.

I had all of the main bearing caps bagged and tagged, so I just cleaned them up, popped all

of the new main bearing shells into place in the block and in the caps, applied plenty of

assembly lube, carefully placed the crankshaft into place, and worked the caps into

place on top of their respective main journals. According to the Bentley manual, there are

2 types of main bolts used. The early type are shouldered and get torqued to 48 ft*lb. The

later type are threaded all the way up to the head, and get torqued to 48 ft*lb plus another

quarter of a turn (90 degrees). I had the later type. The crankshaft is the original from

this engine block (220,000 miles!), and I had it worked over by a reputable machine shop in

our area (R&L engines). They didn't have to grind the journals for oversized bearings because

they were still well within spec. It was a simple radius and polish job. I got the crankshaft

back well packaged, oiled, and looking brand new. It only cost $65. Here is that beauty

of a crank installed:

I didn't get any of the pistons installed because I don't have a ring compressor. Well,

that's not entirely true. I just don't have one that will fit 82.5mm pistons. So my next

ABA rebuild related post will be me making a ring compressor and (hopefully) installing

the pistons and attaching the connecting rods to the crankshaft.

|

|

|

|

Mon Sep 05, 2005

18:15

|

|

|

Today's "down": That nice set of Mahle piston rings that I bought quite

a few months ago to use in my ABA rebuild turns out to be for 1.8 liter VW engines with an 81.0mm bore. If you know the ABA motor, then you

know it's a 2.0 liter with an 82.5mm bore. Had I bothered to look at the label on the bottom of the box after

receiving them, then I would have known right away:

Gah!!! I'm a moron.

That was a real downer after I got myself all excited for reassembly and even put together one piston/rod assembly:

Today's "up"

Today's "up": I got a chance to try Ross-Tech's little diagnostic

procedure to do a sort of crude check of the mass airflow sensor in the black Golf. I think their fuel-trim writeup

was geared toward something other than the ABA cars because the measurement block they said to read for the mass

airflow sensor feedback was 002. I ended up finding it in 003 instead. So I did what they said - while monitoring

the sensor feedback in group 003, I did a run up to redline in 2nd gear. The reading peaked at about 103g/s which

is definitely a little high. The calculation is pretty simple: take the peak reading and divide it by 0.8. The

result should be the approximate horsepower output of the engine. In my case, it's a stock ABA which is supposed

to be 115 horsepower. My peak reading of 103 divided by 0.8 gives 128.75. To reinforce this, I found that there

was a DTC stored in the car's computer:

16487 - Mass Air Flow Sensor (G70): Signal too high

P0103 - 35 - 10 --- intermittent

So that gives me something solid to go on, at least.

|

|

|

|

Sun Jul 24, 2005

22:56

|

|

|

The pistons are nice and clean now, I gave them a final Castrol

Super-Clean bath today and they're now ready for reassembly. This

coming week I should have an update (and pics) of the putting-stuff-back-together

phase.

|

|

|

|

Sat Jul 23, 2005

21:24

|

|

|

Today I had a spare half hour or so to do a little more cleaning

on my ABA pistons, they're starting to look nice:

And here are some pics of the block I

mentioned earlier:

|

|

|

|

Wed Jul 20, 2005

23:21

|

|

|

This is a project that has been in progress for a while now, so this post

is just to provide background info and get up-to-date on

where I am with it now.

Purpose: Perform one of the most basic watercooled VW engine swaps: An OBD-I ABA

2.0 liter block swap. The ABA block is fantastic because it bolts up with the

cylinder heads used on the earlier cars. It also mates with the 020

transmissions and uses the same engine mounting points. In my case, I have an A2

Golf with the factory 1.8 8valve and Digifant engine management. Here is the why:

-My current motor is whipped (poor headgasket, valve stem seals, main bearings).

-200cc increase in displacement (more torque, potential for more power)

-The OBD-I ABA has high quality, forged internals.

-This will allow me to easily use a serpentine belt to drive the alternator rather than a v-belt.

-It's nearly as easy as replacing the stock engine block, so why not do it?

There are a few minor differences between the ABA block and the earlier blocks that

I will need to contend with. First of all, the physical height of the ABA block is

about a quarter of an inch greater. Secondly, the ignition distributor normally used

with the ABA block is different than the distributors used with the earlier blocks (it's hall

sender uses a different number of pulses per revolution and the mounting base is physically

larger). Last of all, there are openings in the ABA block, which are normally used

for crankcase ventilation, that must be blocked off for my purposes.

I will be rebuilding a spare Digifant cylinder head as well as an ABA block that I received

for free from my brother, so that I will be able to swap the whole assembly once the rebuild

is complete.

I have all of the parts necessary for a complete head and block rebuild, the ABA block

has been completely disassembled and pressure-washed and painted (using POR-15), the

cylinder bores have been honed, the crankshaft has been professionally resurfaced by

my favorite local machine shop, and I am nearly done cleaning the pistons. Once the

pistons are cleaned, I can start assembling the block.

|

|

|

|

|

|

A1 parts for sale:

|

Item:

Item: Intake air pre-heat hose (from exhaust manifold shroud to air box), for Scirocco 2 (1982+)

Condition: New

$12

|

|

|

|

A2 parts for sale:

|

Item:

Item: GTI dual-round grille with inner lights, bulbs, and lower trim strip

Condition: Used, lower trim strip is weathered.

$35

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

Item:

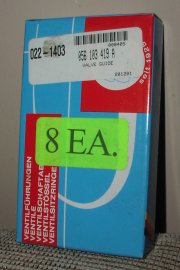

Item: 8 (eight) valve guides, German, standard size, for 8 valve head

Condition: New

$24

Item:

Item: Wheel cylinder (for rear drums, obviously), 2 available.

Condition: New

$12 ea.

|

|

|

|

A3 parts for sale:

|

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

|

|

|

|

A4 parts for sale:

|

Item:

Item: OEM Water pump, ALH engines

Condition: Used, 130,000 miles

$20

|

|

|

|