|

Tue May 13, 2014

17:09

|

|

|

I had been keeping my eyes peeled for a cheap set of wheels for the R32, that I could swap the winter tires onto

and then put the summers on the factory wheels. I had a tough time finding anything that fit the bill, and for

under my budget for used wheels I managed to score a set of brand new Alzors from ECS Tuning. They were on

clearance, and I liked the look well enough (they're replicas of wheels found on the Audi S8). The quality is OK,

though the center caps are pretty poor. I used Siemens tire pressure sensors and didn't have any trouble

with them at all. You just need to keep in mind that the factory tire pressure is a lot higher than you might

think - 42psi both front and back. Get it much below that and you'll get the TPMS warning light.

Here she is, with the summer wheels and after a fresh coat of wax:

After waxing it by hand, I know where all the little imperfections are. There are a few rust spots starting that

I need to nip in the bud (the car is 6 years old, and from Maine, so I'm not too surprised), and the rear bumper

has been repainted... the paint was very well done and I never would have noticed except I can see through a couple

of scratches that the color underneath is deep blue pearl.

|

|

|

|

Tue Mar 11, 2014

18:40

|

|

|

With my growing interest (obsession?) with machining and watchmaking, my automotive adventures

have really tapered off. Nearly everything I have done since my last post has been boring

repair and maintenance, as necessary.

I am happy to report, however, that a recent change in our vehicle line-up has rekindled some

of my passion for cars. I have passed my beloved Mk2 Golf along to a new owner, and have taken

ownership of an R32. Seeing my old Blue drive away for the last time was pretty sad... but her

replacement certainly takes a lot of the sting out of it. She is a Mk5 R32, #2469, in United Gray:

For those not familiar with the R32, it's a really interesting animal. They made 5000 of them for the U.S.

market in 2004 (on the Mk4 Golf platform), then in 2008 they made another 5000 of them for the U.S. market,

on the then-current Mk5 Golf platform. Each one is numbered on a steering wheel plaque, which makes them

feel that little bit more special. In 2004 all U.S. models were equipped with a conventional 6 speed manual,

while in Europe they were the first car offered with the electronic 6 speed sequential manual DSG. The 2008

models for the U.S. market were available only with the DSG. The 2008s came with every goodie VW had to offer,

with the exception of satellite navigation, which was the only option available from the dealer. The dual

zone climate control works great, the heated leather seats are excellent, the brakes are bigger than dinner

plates, the rain sensing wipers are pretty brain-dead but still better than regular intermittent wipers,

the active exhaust is an adorable attempt to appease the government man holding the noise-o-meter, and the Haldex

all wheel drive system combined with the stability program is just fantastic in the bad weather. Even the DSG

is deeply impressive, and this is coming from someone not typically impressed with any electronically controlled

or automatic transmission.

I've wanted an R32 for a very long time. It's really the sound that got me. The VR6 engine sounds good to

begin with, but taken out to 3.2, with a higher compression ratio, asymmetric cams, and a free flowing exhaust,

it sounds like Chewbacca being bludgeoned with the trumpets of heaven. I came across #2469 while half-heartedly

shopping around for something a bit newer that was still interesting and fun. That prompted me to start looking

for other R32s for sale within a couple hundred miles, and I actually found a few others. I really wanted a Mk4

(I think they look and sound better, plus I absolutely prefer a stick shift) but good, honest unmolested examples

consistently sell way over book value and there is no way I'd be able to convince my bank to pony up more than

book value on an auto loan. The best deal I ended up finding was this Mk5 that I had initially noticed, sitting

on an Acura dealer's lot. Asking price was less than the cheapest Mk4 I could find that I considered acceptably clean and

unmodified. The potential problem was worry over whether I could live with the DSG. After taking it for a drive,

though, I completely fell in love with it. The DSG takes some getting used to but the shifts are just lightning

quick. I signed on the dotted line and drove it home that same night.

She has about 94,000 miles, and a bit of

an "interesting" history. From what I can tell, a previous owner (up in Maine) had a pretty awful time with this

car back in 2012. I don't know the details, but it seems to have been a combination of problems with the car that

VW refused to cover under the extended drivetrain warranty, and problems with the dealership itself. I have verified

that all recall work has been done, and that some service work was done under the extended drivetrain warranty

that VW issued to certain specific vehicles known to have used parts from a bad batch of Mechatronic units. So

far everything has operated without fault, with the exception of an obnoxious low speed squeal from the brakes. This

past weekend I tore into the front brakes and cleaned/greased all the appropriate surfaces... no more noises. This

being a VR6 with the mileage it has, I'm planning on some other work when the weather turns nice. First, I need to do

the timing chain guides. Second, I need to replace the motor mounts. After all the issues I've heard about with the DMF

(dual mass flywheel) used in these, I'm tentatively planning on having to do that at some point too. I really should

pull the transmission while doing the motor mounts, to inspect the flywheel. At around $700 for just the part, I'll not

be replacing it "just because".

It's more grown-up than my Mk2, has more creature comforts (versus my Mk2 having none at all), has more room in the back

seat for the kids (plus the back is easer to get in and out of), and has more room in the hatch, plus the versatility of

folding rear seats. I'm on cloud nine!

|

|

|

|

Fri Nov 30, 2007

15:43

|

|

|

The man is gone, but the legend lives on.

|

|

|

|

Tue Sep 18, 2007

17:36

|

|

|

Bridgestone Blizzaks are some of the best snow and ice tires you can get - as

far as studless tires, they may be the best. They aren't cheap, though ...

unless you act now.

Head on over to the

Tire Rack's closeout sale on Blizzak WS-50s

!

You Volkswagen owners may be especially interested,

as their 175/70-13 and 185/60-14 sizes are just $48 each and $53 each,

respectively. That's a steal for these tires. The newer WS-60 model is

moving in to replace the WS-50, so now's your only chance to get them

on the cheap.

We just ordered another set, as Claire's were shot after this past season. This

will be our 3rd set of Blizzak WS-50s.

Happy traction!

|

|

|

|

Mon Sep 03, 2007

16:10

|

|

|

This is my new favorite painting - it was modeled after an old photo of Hans Stuck.

Soon to be hanging on our dining room wall. Thanks again Tim - I couldn't possibly

love it more.

|

|

|

|

Sun May 20, 2007

17:40

|

|

|

This has been a good weekend for tinkering in the garage - it's been lousy

weather:

I spent some time refurbishing a couple of throttle bodies - one of them is for

our A3 Golf:

I've also been practicing polishing valve faces. I'm getting closer to completing

the ABA engine rebuild, so it's time to think about the cylinder head and valvetrain.

Polishing the valve faces helps reduce carbon buildup, and also helps hot spots

from developing (which could lead to detonation problems). I will be polishing

the combustion chambers in the cylinder head as well, for the same reasons. I'll

be having 0.060" milled off the head, and then compensating for the 1.3 degree

cam timing error by using an adjustable cam gear. The final compression ratio

will be 11.5:1 - so I need to do everything I can to promote efficient combustion.

I have a decent technique for polishing the valve faces, which involves glass

bead blasting (to remove carbon buildup) followed by rubbing with crocus cloth

and WD-40, and then using a power drill to spin the valve against a soft cloth

with Brasso metal polish. I haven't been able to get a perfect mirror finish yet,

but I can get them shiny enough to see reflections:

|

|

|

|

Sat Apr 14, 2007

10:52

|

|

|

Ever been curious about the inner workings of the Volkswagen 020 transmissions?

For the uninitiated, 020 refers to non-cable-shifted transmissions found in 4

cylinder Golfs, Jettas, Rabbits, Sciroccos, etc. During a recent trip to visit

my parents down south, my dad and I spent one morning tearing down a 5 speed 020

transmission, just to see what kind of shape it was in and to give me sort of a

crash-course in VW transmission rebuilding. This particular transmission came from

an A3 (Golf/Jetta from 1993 through early 1999), and the A3 Bentley manuals do not

cover the internals workings of the transmissions. Fortunately, however, the A2

Bentley manual covers transmission work in great detail... and the procedures and

diagrams can be applied to the A3 transmissions (the differences are quite minor).

Here we start by removing the output flanges (the flanges that bolt to the inner

CV joints). The first picture shows a small apparatus used to compress the flange

so that the retaining clip can be removed (the flanges are spring loaded). The

second picture shows a puller being used to remove the flange - the puller may or

may not be necessary, depending on how snug the seals fit against the flanges.

Next, the selector shaft cover plate gets removed. The hex recess in the selector shaft cover

plate is 27mm, and 1 1/16" is a nearly perfect fit as well. You can either buy the

official removal tool or just fashion your own using hex bolts and nuts that are either

M18 (for metric) or 5/8"-11 (for SAE). An impact wrench and some penetrating oil

may be necessary to remove the plate. Here is the tool we used, along with the

removed cover plate. We left the selector shaft itself in place for the time being.

The 5th gear housing is the small section bolted on to the very back of the transmission

housing. This 5th gear housing also contains the throwout bearing. Remove the bolts that go

through the fifth gear housing, and lift it off (it may stick, in which case you may

have to work at it with a rubber mallet or deadblow hammer). In the first picture below,

you can see the 5th gear housing being lifted, and in the second picture it is

completely removed.

Now remove the 5th gear lockout plug which threads into the selector shaft housing. In

the first picture below you can see the lockout plug and the reverse light switch

being removed, and in the second picture the selector shaft is being slid out of the

housing.

With the selector shaft removed, you now need to manually operate the shift forks so that

both reverse gear and 5th gear are engaged at the same time. This is necessary to keep

the innards of the transmission locked up so that the hollow bolt on the end of the

input shaft can be removed. I don't have a picture of how the shift forks need to

be manipulated, but it's pretty easy. Look down into the selector shaft housing with

a flashlight, and you should be able to see the shift fork actuators all lined up

in a row, side-by-side. 5th is on one end, and reverse is on the other end. Make

sure all the shift forks are "even" (meaning the transmission is in neutral) and then

press down on the two fork actuators on either end. Now both the input and pinion

shafts should be locked in place and the hollow inset triple-square bolt that holds

the 5th gear assembly on to the input shaft can be removed. You will need the correct

size triple-square bit (the same size used for removing many VW cylinder head bolts)

and an impact wrench. They are not only tight, but loc-tite'd in place.

The 5th gear shift fork now needs to be separated from the shift fork tube. There is

a special tool you can buy to spin the shift fork tube, which is threaded. We just

used a pair of needle-nosed locking pliers (carefully!) to spin the shift fork tube

out from the 5th gear shift fork assembly. In the first picture below, you can see

a small locking plate being pried out of place - that is necessary before the tube

will turn. In the second picture we are removing the forks from the tube using

locking pliers.

Now the two mating 5th gears can be removed. You may have to pry the input shaft

5th gear, as they can sometimes be a tight fit. The mating 5th gear on the pinion

shaft is held in place by a retainer. In earlier transmissions (A1/A2), Eaton-style

retaining rings are used, in A3 transmissions a special clip (pictured below) is

used. The A3 style clip is quite easy to remove using a flat screwdriver. The Eaton-style

clips can be difficult to remove, especially if you don't have flat-nosed

circlip pliers. In the first picture below, the input shaft 5th gear assembly is

being removed. In the second and third pictures, the mating 5th gear on the pinion

shaft is being removed.

With the gears out of the way, we can now access the screws which attach the plate for the

large input shaft bearing to the inside of the transmission case. They are smaller

triple-square screws and are incredibly tight. The best thing to use for these is a

hand impact screwdriver and a good, heavy hammer. In the first picture below you can

see an impact driver being used to remove the screws. In the second picture below, the

screw that attaches the top end of the reverse gear shaft to the housing is being

removed (that makes the case halves a lot easier to separate).

Now remove the bolts securing the two halves of the transmission case. The gasket material

used on these transmissions often causes the case halves to really stick together, so you

may have to work at it with a rubber mallet and some prying. The first picture below

shows the halves being split using a pickle fork and cold chisel. The second and third

pictures below show a trick for separating the large input shaft bearing from the housing.

Wedge the two halves of the case as far apart as possible using screwdrivers, chisels, or

whatever, which will allow the weight of the input shaft to exert downward force on the

bearing - basically, the shaft will be hanging from the bearing. Now use a good, hot

torch flame to heat up the area of the case around the input shaft bearing. The more

you heat the case, the more it will expand and start to release the bearing. You may also

have to tap down on the input shaft while doing this - but many times the whole shaft and

bearing will drop right out on their own.

In the first picture below you can see the bearing starting to drop out from the case. In

the second picture, you can see the whole rear section of the case being removed. The

pinion shaft, input shaft, reverse gear shaft, and differential are now in plain view.

A3 020 transmissions are notorious for having reverse gear problems. The gears are prone

to getting physically chewed and torn up. In the first picture below, you can see the

damage to the reverse gear on the reverse gear shaft. In the second picture, you can

see damage to the mating reverse gear on the pinion shaft.

Now carefuly remove the shift fork assembly, as seen in this picture.

The gear now on the end of the pinion shaft is 4th gear, and you will need to slide it

off while removing the input shaft at the same time, as shown in the first picture below.

The gear may slide right off the pinion shaft, or it might be a very tight fit which

requires prying. In the second picture below, you can see another bearing plate at the

base of the pinion shaft. We need to be able to get to those bolts underneath the

pinion gears.

While you are removing gears from the pinion shaft, you may want to check for end-play

where applicable. Any place you see these Eaton-style retaining rings being used, you

can use feeler guages to measure the gap between the retaining ring and the gear

surface, and that's the end-play. In the first picture below you can see my dad

measuring an 8 thousandths gap. If adjustment is required, retaining rings of different

thickness are available. I am told they are color-coded. In the second picture below,

you can see the pinion shaft with only first and reverse gears remaining. They may

need to be pried loose, which can be a little bit of a pain.

In the first picture below, you can see the pinion shaft stripped bare. The bearing

plate can now be removed, as seen in the second picture. After that, the pinion

shaft itself is free to be removed, as seen in the third picture.

It is pretty common to see the large pinion shaft bearing show a lot of wear. In

extreme cases, as shown in the first picture below, the bearing case will wear completely

through so that the rollers are no longer retained. This is a weak point in the 020

transmission design. The second picture below shows damage to the pinion gear, likely

caused by debris from either the pinion bearing or reverse gears.

The first picture below shows the differential removed from the case (it just lifts out).

The second picture shows damage to the differential ring gear (which mates with our damaged

pinion gear shown above). The third picture shows the rest of the transmission case,

nearly stripped bare.

This is the point where you'd want to decide whether the transmission is worth rebuilding.

In our case, perhaps not (because of the ring and pinion damage). If so, it's a matter

of getting your hands on any replacement parts needed (synchro rings, bearings, gaskets,

gears, etc), then thoroughly cleaning everything, then reassembling.

I am currently working on an A2 transmission, and the disassembly is complete (at the same

stage that we left this A3 transmission). Luckily, the A2 transmission has no reverse

gear damage, no ring/pinion damage, and no bearing damage. As I clean, repair, and reassemble it I will

try to document the process so that y'all can see the rebuild.

|

|

|

|

Fri Feb 23, 2007

17:41

|

|

|

Until quite recently, Meyle has been a brand that I've trusted to be good

quality. Meyle was always one of those "real german parts" brands. Lately

I'm noticing a disturbing trend among Meyle parts. Several months ago I

needed to replace the plastic dipstick tube on my A2. The original tubes

seem to last 10 or more years, but all the replacements (even if they are

OEM) seem to last 2 years at the most. The tube I was replacing on my A2

was a little less than 2 years old, so I wasn't too surprised. The

replacement tube that I purchased was a Meyle brand. I bought it at

Atlantic. I went to press it onto

the metal tube attached to the engine block, and it immediately split apart

at the bottom. On top of that, the dipstick was a real sloppy fit in the

other end of the plastic tube. I returned to Atlantic with the broken part

and they gave me a replacement for free. I came back home and the replacement

part basically shattered when I tried to press it on. I gathered up all the

pieces and headed back to Atlantic, and they confirmed that it was the correct

part. I also took the A2 dipstick with me, and we found that it was a sloppy

fit in any of the Meyle brand tubes that they had in stock. This is also the

same part for the A3s, and one of the owners of Atlantic drives an A3 Jetta

and had recently installed a Meyle dipstick tube on it. We went out to take

a look at his, and it was just the same - broken at the bottom (but still

attached), and a sloppy fit around the dipstick. They had a few of the tubes

in stock that were a different brand, so I went back home with one of those.

The dipstick was a proper fit, and it pressed on just like it should.

Now, fast forward to a couple of weeks ago. Pete's inspection month was here,

and the

TDI Beetle was the first vehicle he made an appointment for. It failed for

rear brakes (no big deal), a small exhaust leak (a pain, but that's life), and

(drumroll please) ... broken sway bar end links. Okay, I'll explain how that

relates. Those sway bar end links were replaced back when we repaired the

damage from the broken timing belt, because we noticed one of them had broken.

That was only in November of last year - about 3 months ago. That is pretty

poor life by anyone's standards. Pete removed the broken end links, and I was

less than surprised to see "Meyle" stamped into them. Real nice. Behold,

the broken Meyle swaybar links:

So, there we have it. I'm not saying that all Meyle parts are junk... I'm

just saying be careful, especially if it's a plastic part. Plastic swaybar

links seem like a terrible idea to me in the first place, but whatever.

|

|

|

|

Fri Feb 09, 2007

21:08

|

|

|

Got my Golf inspected this morning, so that's both cars out of

the way for another year. I stayed up late last night reassembling

my rear brake calipers (I had replaced the piston seals and dust boots)

and installing new parking brake cables. The calipers took a long time

because I goofed on one of them by leaving out a circlip. Things got so bound

up inside the caliper that it took nearly 2 hours just to get the

piston back out. The parking brake cables weren't easy either,

because they didn't fit. I had to shorten the cable tubes (the tubes

that are mounted through the body of the car, which the cables slide

into) in order for the ends to come up far enough to attach to the

parking brake lever. I don't know what the cables that I replaced

were from (apparently something other than an A2 Golf).

|

|

|

|

Fri Jan 12, 2007

19:08

|

|

|

I'm headed down under. Back in 2 weeks. :-)

|

|

|

|

Thu Jan 11, 2007

19:38

|

|

|

Virginia

has passed her 2007 state inspection, so that's one down and one to go. I'm going to be

out of the country on business for the next couple of weeks, and don't have time to get

Blue

inspected, because she needs work on the rear brake calipers first. I'll be doing that

first thing after I get back.

|

|

|

|

Sat Jan 06, 2007

16:18

|

|

|

Sun Dec 17, 2006

18:44

|

|

|

There are a number of interesting cars driven by coworkers of mine, and I'd like to

start mentioning them here. Today I present Bill's 1969 Mustang. Yes, it sounds

as mean as it looks. (click the picture to see a bigger version)

|

|

|

|

Wed Nov 29, 2006

19:02

|

|

|

Well, the TDI Beetle is pretty much straightened out now. The car has been driven daily over the past week, and seems

mechanically sound. We had a high RPM power loss issue that we ended up tracing back to a bad air mass sensor (mass

airflow sensor). The new sensor should have arrived at Pete's house this evening. It's good to have another project

out of the way.

|

|

|

|

Sun Sep 17, 2006

17:40

|

|

|

My apologies for the delay, but my photos from the British International Motor Show

in London are now up on this site. I added a link to them under the "car stuff"

section of this site, and you can go directly to them here:

http://www.digitaldownpour.com/site/carstuff/LMS06/LMS06

|

|

|

|

Fri Jul 21, 2006

19:33

|

|

|

Gone to United Kingdom. Back in 2 weeks, with some pictures from

the London motor show.

|

|

|

|

Sun Jul 09, 2006

08:37

|

|

|

We're pretty close to living in the new house now - most all of our stuff is moved, and our bathroom renovation

is nearing completion. Here is a shot of our new front yard, with our "his and hers" Golfs parked in the

driveway:

Right next to where my blue Golf is parked in the picture above, we had a whitetail deer grazing yesterday

evening. That's pretty cool.

|

|

|

|

Fri Jun 16, 2006

21:10

|

|

|

It's official - we're moving into a new house! Of primary interest is the garage and basement,

which will become the new Volkswagen shop. It'll be nice to finally have a convenient location

for the lathe / milling machine and a nice cement floor to work on.

I haven't had a chance to post here with all of the chaos surrounding the closing,

and now we have to worry about moving all our stuff. My next post may be quite a while

from now.

If you're curious to see pics of the new place, check them out here:

http://www.digitaldownpour.com/ourhouse

The previous owners were still in the process of packing when we took these photos, so

please excuse the mess.

|

|

|

|

Thu May 11, 2006

16:20

|

|

|

The VW Rabbit (or Mk1 Golf in all other parts of the world) is one of my favorite cars

of all time. No, I'm not kidding. Okay, the Rabbit GTI that VW *eventually* sold in

the United States (1983 and 1984 were the only model years that the Rabbit GTI was available

in the US - in 1985, they changed platforms and rebadged the car as a Golf) was very watered

down. The original VW GTI (1976, I believe) was only available in europe and cranked out

a screaming 110 horsepower from a flat-head 1.6 liter engine. The 1.8 that came from

the factory in all US spec Rabbit GTIs was so de-tuned that it produced only 90

horsepower. The Rabbit was a very small and light-weight car and had a super-close-ratio

transmission... so even with only 90hp, it was a quick car (0-50 in 7.2 seconds). Imagine

that same car with an extra 20 horsepower (that's a 22% increase!), and it doesn't take

long to realize that would have been a stunningly quick little car, indeed. VW has a

history of offering softened versions of their european models to the U.S., and it's really

too bad. As generations went by, the cars got softer and heavier (much to the dismay of

the enthusiasts).

The original Rabbit (1975-1984) is now a popular platform for hot motor swaps, and it's not

uncommon to go to a show and see one of these slim, trim 1900 pound bunnies sporting a suped up

late model VW or Audi motor (20v turbos and the narrow angle VR6 being the most common).

The last Waterfest show I went to, I saw a Rabbit run the quarter mile in 11.3 seconds. That's

some pretty serious performance.

The Rabbit is a favorite of mine partially because of what it is (a german engineered, economical,

inexpensive, fun car that is cheap to own and maintain) but also because of what it has the

potential to be. Now fast forward to current times, we have the 2007 model year cars starting

to hit dealerships and what do we see from Volkswagen of Ameria? Why, we have the 2007 Rabbit!

Yes, that's right - the

Rabbit is back

for the 2007 model year. As with the first generation,

it is still called the Golf in europe. The new Jettas have been out for a while - they are

VWs new platform, named the A5. The Golfs built on this platform have been out in europe for

a while now, and have received rave reviews from performance enthusiasts. The GTI version sports

a hot 16 valve turbo with 6 speed transmission, and the A5 chassis is by far the most rigid of

any Volkswagen to date. It's clear that VW has decided to get back in touch with the roots of

it's watercooled heritage (meaning, the Rabbits, Sciroccos, Dashers, and MK1 Jettas), and they're trying

to push this concept even further by appealing to people's fond memories of the old Volkswagen

Rabbit. In my opinion, it appears that they have the goods to back this up. The A5 Rabbit

is touted as being a firm, taut, spirited, and economical car - just like the original A1 Rabbit.

The Rabbit then:

The Rabbit now:

|

|

|

|

Sun May 07, 2006

11:33

|

|

|

Slight change of plan with those General Exclaim UHP tires. They're being used on a brand new

set of 16 inch American Racing wheels instead. We had the wheels sitting around, still in the boxes,

doing nothing. The ultimate plan is to use them on the Corrado, but we may as well get some use out

of them in the meantime. The tires are now mounted on the wheels, but not installed on the car yet.

Here they be:

|

|

|

|

Tue Apr 25, 2006

19:24

|

|

|

I was digging through some old files on the computer this evening, and came

across something that really makes me miss driving my old Scirocco. It's a

sound clip I recorded just by placing a small tape recorder on the passenger's

seat. The clip is pretty short - it starts with me at rest at the intersection

of French Cross Road and Route 9, and then pulling out onto Route 9 and winding

through the first 4 gears. It was many years ago, but as I recall, the reason

I did this was to document how she sounded after a few modifications. This would

have been shortly after I swapped to a big valve cylinder head with g-grind

camshaft, replaced the ignition distributor with the european version (more

aggressive spark curve) and replaced the factory 4-into-1 exhaust manifold and

downpipe with a less restrictive, 4-into-2-into-1 manifold/downpipe. I have

to admit, she sounds even better than I remember.

Here is the recording, in WAV

format.

|

|

|

|

Sat Apr 15, 2006

20:43

|

|

|

Check out the new tires for the 96 Golf, 205/45-16 General Exclaim UHP:

On a related note, who would have thought we'd ever see web site URLs stamped on tires? Check it out:

|

|

|

|

Thu Apr 13, 2006

03:27

|

|

|

Anyone who knows me knows that I'm hooked on snow tires. I started using

Bridgestone Blizzak WS-50s

a couple of years ago, and absolutely love them. We have 2 sets of them - one for my Golf (175/65-14

on black steel rims) and one for Claire's Golf (195/65-14 on a set of factory VW Orlandos).

Blizzaks could be used all year, as they really do perform fairly well in dry conditions as well as

snow and ice, but the rubber compound will wear extremely quickly on dry roads so it's best to switch

over to summer or all-season tires once the nasty weather is gone. So we also have a couple sets

of summer tires that I swap over to during the spring. Last summer, Claire ran my set of cheap

(yet decent looking) American Racing 15x7 wheels with 205/50

Kumho Ecsta 711 tires and I ran my infamous

set of practically-brand-new factory VW 14" snowflake alloys with 195/55

Dunlop SP Sport 8000 tires. The

Dunlops are great tires and I've had them for about 4 years now, only putting a few miles on them

here and there. I should have put them to better use, because now they're getting cracks in the

rubber down in the tread blocks. So this year I had a choice to make - either get new tires for the

14" snowflakes and continue using the 15" wheels and Kumhos on Claire's Golf, or use the 15" wheels

and Kumhos on my Golf (what I originally bought them for, actually) and buy a set of tires to fit

the 16" wheels that our 96 Golf (Claire's) came with from the previous owner. The wheels are just

fine, and look pretty sharp on the car - but the previous owner was running them without

hub-centric adapter rings, which is a big no-no in my opinion. I think the 16" wheels look better

on the 96 than those 15" American Racing rims, so I decided to get some tires for the 16s. I was

planning on either 205/45-16 or, preferably, 225/40-16. After looking, just about the only tire I

could find in 225/40-16 was the Kumho Ecsta 712... and they were about $85 a piece plus shipping plus

mounting/balancing. Ouch. Grumbling the whole time, I started looking for tires in ho-hum 205/45

instead and had pretty good luck finding a deal. I found that General Tire actually makes high

performance summer tires, and their

Exclaim UHP is very reasonably priced.

The reviews on The Tire Rack were great and people here at work have had good luck with General

Tires, and the price was right so I decided to give them a shot. They arrived yesterday, so now I

am just waiting for the hub-centric adapter rings that I ordered to come in. In the meantime, I need

to get the new tires mounted on the wheels and have them balanced... then they can go on the car

as soon as the rings get here.

|

|

|

|

Wed Mar 29, 2006

18:59

|

|

|

The weather outside is fantastic lately, I think the winter weather may finally be over

here in New England (fingers crossed, knock on wood, etc). My thoughts are now turning

toward the seemingly millions of things I have to do now that the days are longer and the

air is warmer.

1995 Jetta

-

Replace evaporative emissions valve (solenoid)

-

Have new all-season tires (purchased last year) mounted on wheels

-

Get some paint on those primer spots behind the rear wheel arches

-

Clean & detail interior

-

Wash & wax exterior

-

SELL IT!

1996 Golf

-

Replace rear dampeners (lots of sag at the moment)

-

Finish prepping & install door moulding strips

-

Purchase hub-centric rings and summer tires to use with set of aftermarket 16" alloys that

originally came with the car

-

Work some Oxyclean magic on that dirty interior

ABA motor rebuild

-

Install that 4th piston oil squirter

-

Fabricate & install crank-case breather block-off plate

-

Convert ABA ignition distributor to work w/Digifant II engine management system

-

Install ignition distributor, oil pump, oil pan, and oil seals

-

Bead blast the currently stripped cylinder head

-

Lap valves

-

Find wicked good deal on decent, streetable camshaft... then buy it

-

Locate spare set of Digifant fuel injectors

-

Send out spare set of Digifant fuel injectors for blueprinting, flow testing, and rebuilding

(if necessary)

-

Install valvetrain components into cylinder head

-

Install cylinder head onto ABA block

1991 Golf

-

Swap summer wheels/tires onto the car

-

Purchase A3-style alternator (serpentine belt driven)

-

Purchase new clutch, pressure plate, and throwout bearing (might as well)

-

Perform the engine swap (see ABA rebuild above), removing all air conditioning equipment, converting to serpentine

belt accessories, and swapping Brospeed header for factory Dual outlet manifold/dual inlet

downpipe in the process

-

Purchase euro "duck-bill" chin spoiler

-

Install duck-bill and small euro bumpers

-

Some paint touch-up needed here & there

-

Take my driver's side Recaro seat up go G&L Interior and have them repair some minor damage

1990 Corrado (G60 body, 2.0 Motronic 16v motor)

-

Resolve the front fender dilemma (it's a long story)

-

Purchase new dampeners for all 4 corners

-

Install new dampeners & stock G60 springs

-

Inspect brakes and refurbish if necessary

-

Troubleshoot slow leak in clutch hydraulics

-

Re-install entire interior (it's currently out of the car)

-

Have new tires (purchased ages ago) installed on new wheels (also purchased ages ago)

-

Complete tune-up

-

Get inspected

-

DRIVE IT LIKE I STOLE IT! :-)

1985 Wolfsburg Jetta

-

*sigh*

-

Get rid of, for practically any price. :-/

1984 Wolfsburg Scirocco

-

Finish re-wiring (part of battery relocation)

-

Replace misc fuel lines & shift linkage pieces

-

Re-install interior

-

Get inspected

-

DRIVE IT AGAIN FOR THE FIRST TIME IN 3 YEARS!

I have no idea how much of that stuff is actually going to happen. Only time will tell.

|

|

|

|

Mon Feb 27, 2006

18:00

|

|

|

Aha! I found my timing light! It's always in the last place you look, eh? Wicked.

|

|

|

|

Mon Feb 06, 2006

16:03

|

|

|

Nothing much to report at the moment, except our cars made it through inspection without

a hitch this year. It's nice to have that out of the way (until next year, at least).

|

|

|

|

Tue Jan 31, 2006

22:33

|

|

|

Behold, screenshots from

Gran Turismo 4 (for Playstation 2). Okay, this game isn't exactly new

anymore ... but it's still worth talking about. Back in the day, the original

Gran Turismo was the whole reason I splurged and purchased a Playstation (the original one). I had

played the game at a friend's house in college, and I was hooked from the moment I played it.

Until then, I had no idea there was a driving simulator like this available for video game consoles.

Sure, it's still "just a game"... but if you're absolutely bonkers for cars like me, then there's massive

appeal that goes far deeper than the game play. The physics are great, the graphics in each version

of the game have always been pretty cutting edge, but there's more than that. Try more than 500

different cars to choose from, each one of them meticulously modeled after the real thing. Not just more

of the same supercars you get to drive in other games, but also real cars that you've probably

driven already in real life. Not only that, most of the tracks are also straight out of reality - Laguna

Seca (with it's dusty pavement and infamous "corkscrew" - what a killer course!), Limerock, Watkins Glen,

and even Monaco. GT4 features more than 650 cars that you can modify to your heart's content.

One of the coolest features that they introduced in GT4 is a photo shoot mode, that lets you view replays

of races from different camera angles, and take snapshots. The snaphots can then be saved to any

mass-storage compliant USB device (thumbdrives, usb hard drives, etc). The above screenshots are

scaled down versions of those snapshots - as you can see, they come out pretty nice. In these particular

pictures, you see one of my favorite cars in the game - a 1976 VW GTI. 1976 was the first year of the

VW GTI, but only in europe - we didn't get them here in the U.S. until the 1983 model year. It was

called the Rabbit GTI here in the U.S., but it was called the Golf GTI in europe. The european 1976 GTI

and the 1983 U.S. spec Rabbit GTI have many differences. They share the same platform, but the 76 has

the coveted round headlights and small taillights whereas the U.S. Rabbit GTIs came with square

headlights and the wide taillights. The engine used in the 76 GTI produced 20 more horsepower than

the Rabbit GTI, despite being 200cc smaller in displacement. The 76 GTI motor (utilizing a Heron cylinder

head) was a beast for being only 1600cc - it produced an impressive 110 horsepower at 6100RPM. The

83 and 84 Rabbit GTI motor (code JH), by contrast, was 1800cc and produced 90 horsepower at 5500RPM.

Okay, that's enough of that for now.

|

|

|

|

Fri Jan 13, 2006

18:54

|

|

|

Okay, this is quite possibly the coolest thing ever. A short video by

Wagenwerks and Matt Crane called "Significant Addiction". What absolutely

makes this video is the shot of the Ferrari rolling by... with a bad,

bad VR6 Rabbit bearing down on it from behind. Quite possibly the

meanest bunny to ever prowl the streets. My favorite part is the very

end of the video, where you get to hear what the Rabbit sounds like as

it takes off. Absolutely insane. Anyway, the whole thing is done

pretty well - excellent soundtrack as well.

The video is here:

http://www.wagenwerks.net/video/wagenwerks-sa.mov

|

|

|

|

Wed Dec 14, 2005

11:20

|

|

|

Heheh. I'm only 52% Mk2 because I'm actually a Mk1 guy at heart. I just can't afford a decent

example of a small-taillight Rabbit right now.

Go to The Old Time Volkswagen Fanciers Society and take their

quiz to find out how Mk2 you are.

|

|

|

|

Mon Dec 12, 2005

18:43

|

|

|

Following in the tracks of my

alarm system post this evening, here is a quick post about another search engine query that brought a visitor

to this site. The query was "catalytic converter removal for good". First of all, don't'. I do not know about other countries, but

here in the US it is illegal to run your car on public roads without a catalytic converter, if it came

equipped with one from the factory. In fact, depending on the state you live in, it may even be illegal

to run your car without a catalytic converter off-road (ie, on a race track). If you are considering catalytic

converter removal for off-road or track use, then I advise you to check with your state government first to see

if it is legal - because it may not be.

There are 2 reasons that people usually have for wanting to remove or bypass their catalytic converter. One

is failure of the existing catalytic converter. If the "guts" of the converter (it's a ceramic honeycomb-like

substance) start to break up then the chunks will start to rattle and eventually clog the rest of the exhaust

system. Legally, your only option is to replace the catalytic converter once this happens. Perhaps the thought

of "hollowing out" the converter (removing the guts) has crossed your mind - well, be aware that it's not only

illegal but it's also possible for a good, experienced mechanic to tell that it's hollow without removing it. If they notice that

during inspection then you will fail (or, at least, you should fail). The other common reason for

catalytic converter removal is

"performance". Catalytic converters cause a little bit of restriction in the exhaust system - in general,

exhaust restriction increases torque output and decreases peak horsepower output. Enough restriction, though,

will decrease torque as well. Conversely, increasing the exhaust flow will generally decrease torque output

at lower RPMs and increase peak horsepower output at higher RPMs. The loss of torque is usually not very noticeable

at all, except in some very small engines that are already tuned for high horsepower (for example, the 1.8 liter

16 valve VW engines). The amount of extra flow that you will gain by getting rid of your catalytic converter

will most likely not be noticeable - however, it can make a small difference in conjunction with other

modifications such as increasing the compression ratio and installing a more aggressive camshaft (or camshafts).

In general, if your exhaust system between the catalytic converter and the engine is still stock, or if your exhaust

system behind the catalytic converter is stock, then you will

not see any significant gains by removing your cat. You will notice a difference in the exhaust sound - that's

about it. The cats used on most cars I've seen are not terribly restrictive (however, some of the older VWs like

Rabbits and 8 valve Sciroccos have small cats that It's easy to see might be restrictive), and so are usually not

hindering exhaust flow significantly. The most beneficial upgrades you can do to your exhaust involve the

mufflers/silencers and the manifold/downpipe (or, header) - not the cat. If you install a performance header

and a free flowing cat-back system and you still require less exhaust restriction, then you can go a couple

of ways. If you want to stay road-legal, then you can purchase high-flow catalytic converters from companies

such as Techtonics Tuning. They offer cats with full 2.5" outlets (keep

in mind you will need the rest of the system behind the cat to be at least that diameter in order to benefit from

it). If you are hell-bent on not having a cat at all, and if you have already checked to see whether it's

legal where you live, then you can find quite a selection of headers and downpipes with longer outlet pipes that

will take the place of your cat and connect directly to the mid-pipe. You can also buy "test pipes" which are just

pipes with a flanged connection which will bolt in place of the cat.

So, in summary, don't be a polluter just because you think you can pick up cheap horsepower gains. If you *really*

think the stock cat is holding back your horsepower output (unlikely, unless your car is either turbocharged or more than

10 years old) then save up the $150-$300 (if you own a VW) for a larger, high-flow cat so that you can increase flow and still keep

the tree-hugging hippies (like me) happy. Oh, I forgot to mention one other benefit of increasing exhaust flow -

it will slightly increase gas mileage. It may or may not be noticeable - depending on lots of other things.

|

|

|

|

Mon Dec 12, 2005

17:55

|

|

|

I will preface this by stating I only have experience with the factory VW

alarms on A3 VWs (that's 1993-1998 Golfs and Jettas, and Cabrios of similar (but not exact)

vintage). I'm not sure if any A2s ever came with factory alarms... perhaps

some Corrados, but I don't know anything about them if that's the case.

Once again, I have noticed a trend in the search engine queries that lead

people to this site. It seems a lot of folks are looking for info on the

factory Volkswagen alarm; particularly, deactivating it and finding out why

it goes off when the battery is reconnected.

Okay, I think I know what the majority of the people looking for info are

*really* after... disabling the alarm altogether because they don't like

it when it goes off. Most common is the "my alarm goes off every time I

disconnect and then reconnect the battery, or every time I jump start the

car". As most VW geeks know, this is the way the alarm is designed - it

is intentional. The best thing to do when reconnecting the battery or jump-starting

the car is to have a friend standing ready to insert and twist the key in

one of the door locks as soon as the alarm goes off. Inserting the key

in one of the doors and twisting it in the unlock direction is the official

method for deactivating the alarm on these vehicles, unless you are lucky

enough to have a keyless entry system (in which case, you have a little

button on your key fob that will silence the alarm).

I'm afraid I can't endorse bypassing the factory alarm system (not that my endorsement

is actually worth anything). First of all, it's not a trivial task. The system was

purposely designed to be inaccessible and difficult to disable and/or remove. The Alarm

system is also integrated with the central locking system. Not only is it difficult to

bypass or remove the factory alarm, but it really shouldn't be necessary (unless you are

replacing it with an aftermarket system). Disconnecting the battery isn't something that

should have to be done on a regular basis, and likewise for jumpstarting. If

you're needing to jumpstart your vehicle all the time, you'd be best off fixing

the problem rather than killing the alarm. A consistently flat battery is typically

the result of a battery that will no longer retain a charge, an electrical problem

that is keeping the battery from being charged, or an electrical problem that

constantly draws power from the battery even when the car is off.

The other problem you may have with the factory alarm system is that it sounds

when it shouldn't. I had that problem on our 96 Golf. The alarm would sometimes fail to deactivate

when the doors were unlocked. When the alarm did deactivate, it would reactive

itself again once the engine was started, and so opening the door again to get out of

the vehicle would cause the alarm to sound. It was incredibly frustrating, and it

took a whole night to troubleshoot. We started by checking the wiring that runs into the

front doors below the a-pillar (those accordion-like rubber boots that run between the front

of the front doors and the main body of the car). There are switches in the front door locks

that activate and deactivate the alarm system. When you lock a door, the alarm becomes activated

(meaning that it will sound if it senses an event). When you unlock a door, the alarm deactivates

and you can open doors without the alarm sounding. My first thought was that there was

either a nearly-broken connection in the wire providing the deactivation signal, or a short

involving the wire providing the activation signal... or perhaps some combination of both.

Everything seemed to check out, though - the switches were still intact and functioning correctly,

and the wiring going into the body of the car from the door was just fine. After studying the

wiring diagrams in the Bentley book for quite a while, it seemed that the central locking system

control module was related to the alarm system. The central lock module itself is located in the

rear of the car, in the luggage compartment. It will be encapsulated in a 2 piece styrofoam shell.

In Jettas, it is on the driver's side of the car,

up against the side of the luggage compartment (pull the carpeting back the goes up that side, and

you will see it wedged in the body panel above the fender). In Golfs, it is on the passenger's side

of the car, just next to the tail light (you will have to pull back the carpeting going up the

side of the compartment in order to see it). The vacuum pump for the locking system (the locks

are vacuum actuated) is contained in the same housing as the electronic control module, so don't be

surprised when you see a vacuum line attached to it. If you need to disconnect the vacuum line,

squeeze the base of the connector with a pair of pliers, and you should be able to work it free.

If you are having funky alarm problems, then try disconnecting the electrical connections going

to the central locking module and see if the problem goes away. If so, then the locking module

is your problem. That's what my problem ended up being. Opening up the module housing, we

found some water inside it, and the circuitry was badly corroded and burnt. You may want to buy

this part used if you need to replace it. New ones are $280 and upward, as of this writing.

|

|

|

|

Mon Dec 05, 2005

18:55

|

|

|

I finally got around to swapping one set of our snow tires onto

Claire's Golf (that's the black one) tonight. Yesterday we had

our first real accumulation of snow, so I figured it was time. I

normally like to get them on before the first snow, though -

so they're a little late this year. I still have to put our

other set of snow tires on my blue Golf - maybe tomorrow night.

All season tires are fine and all, but a good set of snow tires

just makes an unbelievable difference. This is the 3rd year I've

been running snow tires in the winter, and so far I have used

only

Bridgestone Blizzak WS-50s. Out of all the reviews I read,

they seemed to get the most praise, so I bought one set to use

on the Jetta I used to drive then (the red 95 Jetta that we still own

and use as a spare vehicle). When choosing a size for your snow

tires, in general you want to go skinnier than the standard tire

size for your vehicle. In my case, the stock tire size was

185/60-14 (185 is the width in millimeters, 60 is the percentage

of the width that makes up the sidewall height, and 14 is the

diameter of the wheel they are designed to fit, in inches) so

I went for 175/65-14. A narrower tire gives you an advantage in

snow and slush, because it cuts through with less of a "plowing"

effect. I would have liked to go for a 165 width tire, but the

Blizzak WS-50 does not seem to be available in that width on a 14

inch rim.

My first season with those Blizzaks was phenominal. I was so

impressed with them, in fact, that when I bought my blue Golf

I bought another set. That set came from a user on VWVortex

who was moving from Pennsylvania to Florida and had only used

them for one season. These Blizzaks were 195/60-14, which is

actually one size wider than the factory width. That really

didn't seem to make much of a difference, though. I am hooked

on these things. Even on wet ice, these tires somehow manage to

find grip. Bridgestone says they use a special compound on these

tires that give them ice traction equivalent to studded snow

tires, and I believe it. The only gotcha is that once the

tread wears down to 45%, the "special" compound is gone and

all that remains is tread made of standard winter tire compound.

|

|

|

|

Wed Nov 30, 2005

20:00

|

|

|

With the holiday season rapidly approaching, updates will be

even less frequent here. My wife and I will be visiting

relatives in the deep south for a good portion of December

and until then there's plenty of Christmas preparation to

get through. Busy, busy.

Happy holidays, y'all!

|

|

|

|

Sun Oct 30, 2005

15:27

|

|

|

Thu Oct 20, 2005

19:48

|

|

|

Pfff. I ran out of gas on the way home from work today. I was really pushing my luck - the

fuel guage had been hovering just above the red for quite a while, and I had over 400 miles

on the trip odometer (which I reset on every fill-up). So it was really no surprise when my

poor Golf started sputtering and eventually died. Luckily, I was only 1/4 mile or so from

home. Luckier still, the car died right in front of some apartments and there was a guy outside

talking on a cell phone. He kindly ended his call so that I could quickly call home. Minutes

later, help showed up in the form of my father-in-law with a couple gallons of gasoline.

I was back on the road so quick that I think it barely even qualifies as a break-down.

|

|

|

|

Mon Oct 03, 2005

16:31

|

|

|

Well, I've noticed a *lot* of hits coming from google lately in the access log for

this site. Quite a few folks seem to be looking for info on Volkswagen camshaft position

sensor problems. It's no surprise, really. Lots of people have problems relating to

this sensor, and the online forums are full of posts by people looking for answers.

My own experience with this sensor is on ABA engines, but as far as I know all of the

VW 2.0 liter 8 valve Motronic engines use this sensor.

So, where is the camshaft position sensor and what does it do? The sensor is physically

located within the body of the ignition distributor. It's electrical connector is on

the outside of the distributor. The sensor feeds a signal back to the ECU (onboard computer).

The name "camshaft position sensor" is kind of misleading. The computer uses the

signal to determine the position of the camshaft; however, it does so on the assumption that

the camshaft/intermediate shaft/crankshaft timing is 100% correct. To elaborate, the ignition

distributor is directly driven by the intermediate shaft. The intermediate shaft is driven

by the timing belt, which also drives the camshaft and the crankshaft. This means that

the computer can calculate the position of the camshaft by knowing the position of the

ignition distributor. The camshaft position sensor is actually a hall sensor (hall sender)

that sends a signal once per revolution of the distributor. One revolution of the distributor

equals one revolution of the intermediate shaft, which equals one revolution of the camshaft.

So that's why it's called the camshaft position sensor when it actually lives in the

distributor.

So, why do so many people have problems with this critter? So many people have problems

because they have timing belts replaced by people who don't appreciate how much the whole

system relies on the timing between the camshaft, intermediate shaft, and

crankshaft being absolutely correct. The ECU has enough input from other sensors on the

vehicle to tell if the intermediate shaft is off by as little as one tooth. The DTC (Diagnostic

Trouble Code, or Fault Code) that usually plagues VW owners is "Implausible Signal". That

means that the ECU has detected that the signal from the camshaft position sensor cannot

possibly be correct, based on other feedback from the engine. If your timing is off by a tooth,

then this is the message you will get.

So, is that it? My timing is just off? Well, not necessarily. If you have the "Implausible

Signal" code stored, then it's probably your timing. However, you may have a different message

stating that the signal is either open or shorted to ground. If you have such a message, then

timing is not the problem (at least, timing isn't the *only* problem). This is the message

you will see if the sensor is faulty (or disconnected); however, it could also indicate a wiring

problem. Don't replace the sensor until you have thoroughly checked the wiring between the

sensor and the ECU. Using a multimeter, check for open circuits, and also check for continuity

between the signal wire and ground (there shouldn't be any!).

I think it's my timing! What should I do? If you had the timing belt installed by someone else, then

hopefully it was a VW specialist who will readily admit their mistake and correct it. If you took

it to an ordinary shop. then you'll likely have a hard time with that... and they'll probably even

try to charge you so they can replace the sensor that is almost certainly still fine. If you're the

one who did the timing, then re-do it until you get it right. I rarely get it right on the first

try. so don't feel too bad. You must follow the procedure in the Bentley manual exactly as they

say. And make sure you are following the procedure for the correct engine. On many of the newer

VW engines, such as the ABA engines, the marks on the v-belt pulleys are no longer used for

timing. For these engines, the mark on the camshaft sprocket gets aligned with a mark on the

inner portion of the plastic timing belt cover, the crankshaft gets aligned so that the #1 cylinder

is at TDC (top-dead-center) (which can be done by lining up the TDC mark on the flywheel with

the "pointer" mark on the inside of the timing hole in the transmission bellhousing), and the

intermediate shaft must be positioned so that the ignition rotor points directly to the mark

on the distributor housing. Consult the Bentley manual for details, and pictures. *DO NOT*

attempt any of this unless you know what you are doing. Seriously, you can damage the engine

internals (valves/pistons) otherwise. I take no responsibility for any damage you cause. Many,

many people have this problem after having a timing belt replaced. If you are going to have the

belt replaced, I highly recommend you have it done by a VW/Audi specialist. It will be more

expensive, but they'll be far more likely to get it right.

Yikes, that's a lot of info! Yes, it is - but that's not all of it. I recently bought an A3

Golf with this problem, only it was caused by something a little different. The previous owner

had swapped around all of the plug wires so that the firing order was still correct; however, the

plug wire for the #1 cylinder was no longer plugged into it's correct location. Basically,

the wire positioning was "rotated" a little bit. The ECU *requires* that the plug wires be installed

in their correct locations (#1 wire gets plugged in closest to the timing mark on the distributor

body). Otherwise, the ECU will think that one cylinder is firing when another is firing. The

car will still run, but you will never get rid of that code and the check engine light will

stay on. So, if you've recently replaced your plug wires (or had someone else do it), make

sure to check that they are installed correctly.

I apologize for this long and tedious post, but it's my hope that somebody will find it useful.

I will try to periodically do a post like this, where I address issues that I can see people

are searching for.

|

|

|

|

Tue Aug 30, 2005

18:13

|

|

|

Since I'm off work for the week and Claire's current daily driver needs some work, Claire

has been borrowing my rowdy little A2 to go to school during the day. Yesterday, when

Claire went to the car after class, there was something on the windshield pinned under

the wiper blade. It was this:

It's kind of hard to tell whether it's signed "Jon" or "Jen", but whoever you are...

sorry. :) I still have a 2.0 liter engine to install, body and paintwork to do, and

I really have to do something about the exhaust. Sometimes it's kind of fun driving

around with nothing but a Flowmaster to hush the demonic roar... but then sometimes

I wish my exhaust wasn't loud enough to wake the dead. Anyhoo...

|

|

|

|

Tue Jul 26, 2005

21:23

|

|

|

I got home later than usual from work today, and I haven't been doing anything except

working on this site. Perhaps there will be new and exciting stuff tomorrow *fingers crossed*

|

|

|

|

|

|

A1 parts for sale:

|

Item:

Item: Intake air pre-heat hose (from exhaust manifold shroud to air box), for Scirocco 2 (1982+)

Condition: New

$12

|

|

|

|

A2 parts for sale:

|

Item:

Item: GTI dual-round grille with inner lights, bulbs, and lower trim strip

Condition: Used, lower trim strip is weathered.

$35

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

Item:

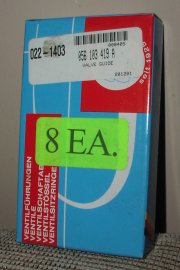

Item: 8 (eight) valve guides, German, standard size, for 8 valve head

Condition: New

$24

Item:

Item: Wheel cylinder (for rear drums, obviously), 2 available.

Condition: New

$12 ea.

|

|

|

|

A3 parts for sale:

|

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

|

|

|

|

A4 parts for sale:

|

Item:

Item: OEM Water pump, ALH engines

Condition: Used, 130,000 miles

$20

|

|

|

|