|

Mon Nov 23, 2015

11:20

|

|

|

A buddy of mine recently tweeted something about rodent damage to his car, and it being expensive to fix, and that

reminded me to get off my duff and put up this post recounting my brush with automotive mouse damage earlier this

year. Mice like confined, dark, warm areas and cars are just full of those. Some of the worst stories involve mice

chewing through air filters in the airbox, and the debris then getting sucked directly into the engine and causing

internal engine damage. Obviously expensive, but then also a very obvious problem. At the other end of the critter

damage spectrum is wiring damage. One one hand, a damaged wire or connector can be easily fixed (ok, so perhaps

your mechanic would ding you with replacing an entire wiring harness, which could be expensive, but technically you

can splice to repair the damage for very little cost), but on the other hand the symptoms can literally be anything

and the root cause of the problem can be extremely time consuming to find, often requiring special equipment. If

your mechanic spends all day chasing down electrical gremlins, that is already quite a repair bill just in labor.

And often, since many shops are under such pressure to fix a car and get it out the door, the job will involve swapping

out a lot of parts that are actually fine, further adding to the repair bill (the extra labor and, if the shop is

trying to pull a fast one, they may even charge you for new parts that weren't necessary). Let us take my latest

mousecapade as an example, and along the way we shall consider how things might have gone down, had I taken the

car to a shop.

This story involves my Mk5 R32. Our neighbors across the street, wonderful folks, have a son who is a real gearhead

and worked as a mechanic for a while. He appreciates cars, and I know he loves R32s. He was stationed out west

and when I heard he was coming home for a visit I thought to myself "Wow he hasn't seen the R32 yet... I bet he'd

like to take it for a drive". So he and I got to chatting outside one day and I told him he was welcome to take

her for a spin if he'd like... of course, he took me up on the offer. We both got in, I gave him the rundown on

how the DSG works, how to switch off the traction and stability control, etc. He went to start the car... and nothing.

Dash lights on, but no attempt made by the starter to turn over the engine. I said "buckle your seatbelt, this car

might have one of those safety interlocks" (I was pretty sure it didn't, but this was my hopeful thinking). He

buckled, tried again, and the engine roared to life... then died after a split second. Now the dash was lit up like

a Christmas tree and again the engine wouldn't turn over. This guy felt just awful, because he knew all too well

how I must have been feeling at that moment, and even though he must have known deep down it was luck of the draw

rather than anything that was his fault, he still felt like he had broken my baby.

During some previous work I had noticed a mouse nest underneath the raintray cover, that I had removed... so I

immediately started to suspect some kind of rodent damage. Keep that in mind, that if that hadn't already been in

my mind this whole thing could have drawn out even longer. This

is the first CAN bus car I've owned, so I had to get an updated version of Ross-Tech's interface to be able to read

all of the controller modules. While I was waiting for the new interface to arrive, I spent a bunch of time physically

inspecting all the wiring I could get to. I tore down the rain tray and engine bay enough to inspect all the wiring and

connecotrs there, I removed the bellypan to inspect everything unerneath the car, I stripped everything out of the dash

to inspect as much as I could of the wiring in the dash and footwells, and I stripped out the rear luggage compartment to

inspect everything in there. Absolutely no sign of any infestation, everything was squeaky clean. It took several days

of free time to do all that. When my new vag-com interface arrived, I hooked it up and did a scan. There was an unmanageable

number of faults logged, across all of the different modules,

with no apparent rhyme or reason to them. I saved them, cleared the system, then attempted to start the car again.

The engine fired up ran well. The check engine light was on and the traction control and all wheel drive were disabled.

I performed another scan and this time got a much shorter list of faults, most of them complaining about the controller

for the Haldex AWD module being offline. The Haldex unit is about $800, if you catch a deal on one... I certainly

was not looking forward to replacing it. But with the wiring having been inspected, I was starting to come to the

conclusion that it must be the Haldex unit. They are notorious for going bad, especially in areas like New England, where

the climate accelerates corrosion around the connector, eventually working its' way inside the module itself. I

inspected the connector on my module, and it was beautifully clean. Let's pause for a moment and consider what a shop

might have done if they were working on the car. They would have started with a system scan, of course, although the

car would have needed towing to the shop because it was immobile to start with. Right away you've paid for towing, and

for diagnostics scan. They would have been faced with the wall of fault codes and then would have either cleared them

and re-scanned (as I did), or just gone ahead and assumed that the problem was the Gateway controller module (the common

link between all the CAN bus modules), and either replaced it or spent a lot of time troubleshooting it. They might have

even replaced it, re-scanned, found that most of the codes were gone, and thought that they had legitimately fixed part of

the problem. We're well over $1500 here so far (the gateway module is very expensive, difficult to get to, and requires

special equipment to code to the rest of the system so that it will function properly), and nothing has actually been fixed

or diagnosed yet. Now, faced with codes mostly pointing to the Haldex controller being offline, they might have been

diligent enough to at least check for a good ground at the Haldex module plug, as bad grounds are also a common problem.

In my case, the ground checked out fine. To test the CAN bus signal wires would take something better than a common

multimeter, I sure didn't have the means to test them. At this point a shop could very well justify replacing the Haldex

module, which is a bit of a pain if you don't either have some special or modified tools, or drop down the rear drivetrain

a little bit. Even once they found that the replacement module didn't make any difference, they could easily avoid the

hassle and cost of swapping the parts back out by simply charging the customer for a new module anyway. Most customers

wouldn't know any better than to throw up their hands and curse Volkswagen's ineptitude over the supposed failure of such

an expensive part. Two things were holding me back from ordering a new Haldex module. First, of course, was the price.

Second, was the fact that there were some other seemingly unrelated fault codes that I'm sure popped up at exactly the

same time. And I wasn't about to spend $800+ on a part when coincidence was part of the equation. I had other symptoms

and fault codes logged that turned out to be caused by my own foolishness... I had placed one of the big power distribution

fuses in the engine bay back in the wrong spot when I was doing that first round of inspection and troubleshooting, and that

was causing my fresh air blower, sunroof, and headlight washers to stop working (and throw associated codes, of course).

Even with that addressed, I had a strange beahavior with my fuel guage. It would only read up to, but not beyond, halfway.

With a full tank of gas, the gauge would stay at half full until the actual level dropped below half, and then it would read

the correct amount. There were no faults stored that seemed related to the fuel sender. How could that be related to the Haldex

module going down? Electrically, they had nothing directly in common. It was about this time that someone replied to a

thread I had started over on the Ross-Tech forums, suggesting that I take a look under my back seat. This fellow said that

the R32 has two fuel pumps and two fuel level sending units. On one side of the car, the wiring for that fuel pump and sending

unit physically runs right next to the wiring going to the Haldex control module. That sounded fantastic to me, so I took up

the rear seat and removed the cover plate for the pump on the passenger side... everything looked perfect. Under the cover

plate on the driver side, though, was an entirely different story. Here is what I found:

Some little furry friends had made a nice, cozy home in there complete with all the terrible tasting licorice they could eat.

Both wiring harnesses had been chewed through, there were only a couple of wires hanging on by a strand or two of copper.

The little rascals didn't even have the courtesy to leave me enough wiring out of the connectors to splice back in. They had

chewed most of the wires right up into the back sides of the connectors, so that I was faced with un-pinning each connector, uncrimping

each pin, then re-crimping it onto a freshly stripped wire. A few of the wires I was able to solder, barely. Here again, once

a repair shop had found this damage, they would not have wasted their time with a repair, they would have ordered whole new wiring

harnesses. It looks like to replace those harnesses you'd have to drop down the fuel tank and the whole rear end a little bit, so

I'm sure it would be a few hours of labor on top of the already steep cost of the harnesses themselves. Had a shop started with that

seemingly unrelated fuel gauge quirk as the basis of their investigation, then they would have quickly found the real source of

the problem. But worst case a customer could have been easily gouged for both replacement harnesses, replacement CAN bus gateway

module, and replacement Haldex module (the new ones do not come with the Haldex clutch solenoid, so a new seal kit for that would

be necessary also) as well as a couple of days labor (if they had burned most of a day chasing down the wiring and getting

nowhere, as I did). This could have been a $4000 repair bill. It took a lot of blood, sweat, and tears, but I got through it

without paying any cash and everything has been working perfect since then. The exposed copper wiring, where it had been chewed

through, was corroded enough that I think the mouse (or mice) had been there for quite some time.

In summary, what appears to have happened was when the last of the wiring for the Haldex module finally let go (or was chewed through),

it must have spiked the CAN bus signal lines and caused all the other modules to momentarily lose their grip on reality. I'm pretty

lucky none of the modules were damaged, I think.

For the morbidly curious, here is my scan after clearing the initial set of codes from "the incident". This was the set of relevant

codes:

Saturday,30,May,2015,16:24:30:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 01: Engine Labels: 022-906-032-BDB.lbl

Control Module Part Number: 022 906 032 KR HW: 022 906 032 GP

Component and/or Version: R32-DQ-LEV2 G 1098

Software Coding: 0000178

Work Shop Code: WSC 01279 785 00200

VCID: 65CB9A1FAC5FCA09FD9-8030

No fault code found.

Saturday,30,May,2015,16:24:48:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 02: Auto Trans Labels: 02E-927-770.lbl

Control Module Part Number: 02E 300 011 CC HW: 02E 927 770 AD

Component and/or Version: GSG DSG 082 1405

Software Coding: 0000020

Work Shop Code: WSC 04940 001 00001

VCID: 52A151C3CDD14DB188B-8007

No fault code found.

Readiness: 0000 0000

Saturday,30,May,2015,16:21:23:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 03: ABS Brakes Labels: 1K0-907-379-MK60-A.lbl

Control Module Part Number: 1K0 907 379 AB HW: 1K0 907 379 AB

Component and/or Version: ESP 4MOTION MK60 0102

Software Coding: 0021128

Work Shop Code: WSC 01279 785 00200

VCID: 72E1F1436D912DB168B-8027

3 Faults Found:

01312 - Powertrain Data Bus

014 - Defective - Intermittent

01315 - Transmission Control Module

004 - No Signal/Communication - Intermittent

01324 - Control Module for All Wheel Drive (J492)

004 - No Signal/Communication

Saturday,30,May,2015,16:21:53:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 08: Auto HVAC Labels: 1K0-907-044.lbl

Control Module Part Number: 1K0 907 044 BS HW: 1K0 907 044 BS

Component and/or Version: ClimatronicPQ35 120 1111

Software Coding:

Work Shop Code: WSC 00000 000 00000

VCID: 79F3C66F30E75EE9291-802C

2 Faults Found:

01316 - ABS Control Module

004 - No Signal/Communication - Intermittent

01314 - Engine Control Module

004 - No Signal/Communication - Intermittent

Saturday,30,May,2015,16:22:17:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 09: Cent. Elect. Labels: 3C0-937-049-30-H.lbl

Control Module Part Number: 3C0 937 049 AJ HW: 3C0 937 049 AJ

Component and/or Version: Bordnetz-SG H54 2202

Software Coding: 668F8F214004150047140000001400000008730B5C000100000000000000

Work Shop Code: WSC 01080 444 59251

Additional Info: 1K1955119E Wischer 050102 021 0501 1K0955559AF RLS 140907 046 0204

VCID: 71E3FE4F689716A9911-8024

6 Faults Found:

02092 - Enabling Heated Seat

009 - Open or Short to Ground

Freeze Frame:

Fault Status: 01101001

Fault Priority: 5

Fault Frequency: 1

Reset counter: 67

Mileage: 177485 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

ON

Voltage: 13.40 V

ON

ON

OFF

OFF

OFF

00924 - Relay for Headlamp Cleaning System (J39)

009 - Open or Short to Ground

Freeze Frame:

Fault Status: 01101001

Fault Priority: 4

Fault Frequency: 1

Reset counter: 67

Mileage: 0 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

OFF

Voltage: 12.40 V

OFF

ON

OFF

OFF

OFF

01321 - Control Module for Airbags (J234)

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177484 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

ON

Voltage: 11.90 V

ON

ON

OFF

OFF

ON

01314 - Engine Control Module

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177484 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

ON

Voltage: 11.90 V

ON

ON

OFF

OFF

ON

00466 - Control Module for Steering Column Electronics (J527)

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177485 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

OFF

Voltage: 12.35 V

OFF

ON

OFF

OFF

OFF

01309 - Power Steering Control Module (J500)

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177484 km

Time Indication: 0

Date: 2005.09.13

Time: 31:63:63

Freeze Frame:

ON

Voltage: 11.90 V

ON

ON

OFF

OFF

ON

Saturday,30,May,2015,16:22:43:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 0F: Digital Radio Labels: 8E0-035-593-SIR.lbl

Control Module Part Number: 8E0 035 593 H HW: 8E0 035 593 H

Component and/or Version: SDAR SIRIUS H06 0080

Software Coding:

Work Shop Code: WSC 00000 000 00000

VCID: 2E592533B9294951CC3-807B

1 Fault Found:

02635 - Tuner Not Enabled/Activated

000 - -

Freeze Frame:

Fault Status: 01100000

Fault Priority: 7

Fault Frequency: 5

Reset counter: 190

Mileage: 172695 km

Time Indication: 0

Date: 2000.00.00

Time: 18:48:00

Saturday,30,May,2015,16:23:03:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 15: Airbags Labels: 1K0-909-605.lbl

Control Module Part Number: 1K0 909 605 AB HW: 1K0 909 605 AB

Component and/or Version: 6T AIRBAG VW8R 034 8000

Software Coding: 0013908

Work Shop Code: WSC 01269 785 00200

Additional Info: 1K0959339G BF-Gewichtsens. 007 0007

Additional Info: Geraet 00200

VCID: 6CDDEF3B4FB5FB41A27-8039

1 Fault Found:

01312 - Powertrain Data Bus

014 - Defective - Intermittent - MIL ON

Saturday,30,May,2015,16:25:40:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 16: Steering wheel Labels: 1K0-953-549-MY8.lbl

Control Module Part Number: 1K0 953 549 AQ HW: 1K0 953 549 AQ

Component and/or Version: J0527 036 0070

Software Coding: 0012122

Work Shop Code: WSC 01279 785 00200

Additional Info: XXXXXXXXXXX E0221 002 0010

Additional Info: Geraet 00200

VCID: 0103AE8F58370629611-8054

No fault code found.

Saturday,30,May,2015,16:23:44:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 17: Instruments Labels: 1K0-920-xxx-17.lbl

Control Module Part Number: 1K6 920 974 D HW: 1K6 920 974 D

Component and/or Version: KOMBIINSTRUMENT VDD 1216

Software Coding: 0007203

Work Shop Code: WSC 01052 444 68459

VCID: 356B0A5F5C7F7A898D9-8060

2 Faults Found:

01315 - Transmission Control Module

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177485 km

Time Indication: 0

Date: 2000.00.00

Time: 01:02:16

01312 - Powertrain Data Bus

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 2

Fault Frequency: 8

Reset counter: 99

Mileage: 177484 km

Time Indication: 0

Date: 2000.00.00

Time: 12:06:41

Saturday,30,May,2015,16:24:06:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 19: CAN Gateway Labels: 1K0-907-530-V3.clb

Control Module Part Number: 1K0 907 530 L HW: 1K0 907 951

Component and/or Version: J533 Gateway H07 0052

Software Coding: ED831F075003020000

Work Shop Code: WSC 01279 785 00200

VCID: 30653B4BA31D5FA1DEF-8065

4 Faults Found:

01312 - Powertrain Data Bus

014 - Defective - Intermittent

Freeze Frame:

Fault Status: 00101110

Fault Priority: 1

Fault Frequency: 1

Reset counter: 255

Mileage: 177484 km

Time Indication: 0

Date: 2000.00.00

Time: 12:06:43

01315 - Transmission Control Module

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00110100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177485 km

Time Indication: 0

Date: 2000.00.00

Time: 01:02:18

01324 - Control Module for All Wheel Drive (J492)

004 - No Signal/Communication

Freeze Frame:

Fault Status: 01100100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 59

Mileage: 177485 km

Time Indication: 0

Date: 2000.00.00

Time: 00:11:57

00466 - Control Module for Steering Column Electronics (J527)

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00110100

Fault Priority: 2

Fault Frequency: 1

Reset counter: 99

Mileage: 177485 km

Time Indication: 0

Date: 2000.00.00

Time: 00:00:01

No response from AWD controller (address 22)

Saturday,30,May,2015,16:27:12:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 25: Immobilizer Labels: 1K0-920-xxx-25.clb

Control Module Part Number: 1K6 920 974 D HW: 1K6 920 974 D

Component and/or Version: IMMO VDD 1216

Software Coding:

Work Shop Code: WSC 00000 000 00000

VCID: 356B0A5F5C7F7A898D9-8060

No fault code found.

Saturday,30,May,2015,16:27:35:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 37: Navigation Labels: 1K0-919-887-MFD2.lbl

Control Module Part Number: 1K0 919 887 G

Component and/or Version: Navigation 0050

Software Coding: 0000101

Work Shop Code: WSC 01279 785 00200

VCID: 3D7B127F644FA2C9459-8068

No fault code found.

Saturday,30,May,2015,16:27:49:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 42: Door Elect, Driver Labels: 1K0-959-701-MIN3.lbl

Control Module Part Number: 1K0 959 701 M HW: 1K0 959 701 M

Component and/or Version: Tuer-SG 006 120A

Software Coding: 0001077

Work Shop Code: WSC 01279 785 00200

VCID: 3875036B4B6D87E196F-806D

2 Faults Found:

00466 - Control Module for Steering Column Electronics (J527)

004 - No Signal/Communication - Intermittent

01321 - Control Module for Airbags (J234)

004 - No Signal/Communication - Intermittent

Saturday,30,May,2015,16:28:09:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 44: Steering Assist Labels: 1Kx-909-14x-44.clb

Control Module Part Number: 1K1 909 144 M

Component and/or Version: EPS_ZFLS Kl.141 H08 1901

Software Coding:

Work Shop Code: WSC 00000 028 00001

VCID: 356B0A5F5C7F7A898D9-8060

No fault code found.

Saturday,30,May,2015,16:28:30:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 46: Central Conv. Labels: 1K0-959-433-MAX.clb

Control Module Part Number: 1K0 959 433 CT HW: 1K0 959 433 CT

Component and/or Version: KSG PQ35 RDK 052 0221

Software Coding: 139006885103281B0904058FB0080A04889C00

Work Shop Code: WSC 00000 785 00200

Additional Info: Sounder n.mounted NGS n.mounted

Additional Info: IRUE n.mounted

VCID: 040DA79B472513014A7-8051

1 Fault Found:

00466 - Control Module for Steering Column Electronics (J527)

004 - No Signal/Communication - Intermittent

Freeze Frame:

Fault Status: 00100100

Fault Priority: 4

Fault Frequency: 1

Reset counter: 99

Mileage: 177485 km

Time Indication: 0

Date: 2000.00.00

Time: 00:00:01

Saturday,30,May,2015,16:28:45:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 47: Sound System Labels: 3C0-035-456.lbl

Control Module Part Number: 1K6 035 456 B HW: 1K6 035 456 B

Component and/or Version: 08K Audioverst. 0006

Software Coding:

Work Shop Code: WSC 00000 000 00000

VCID: 2B5F2C278A3B3C79EBD-807E

No fault code found.

Saturday,30,May,2015,16:29:02:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 52: Door Elect, Pass. Labels: 1K0-959-702-MIN3.lbl

Control Module Part Number: 1K0 959 702 M HW: 1K0 959 702 M

Component and/or Version: Tuer-SG 006 120A

Software Coding: 0001076

Work Shop Code: WSC 01279 785 00200

VCID: 3973066F70679EE9691-806C

2 Faults Found:

00466 - Control Module for Steering Column Electronics (J527)

004 - No Signal/Communication - Intermittent

01321 - Control Module for Airbags (J234)

004 - No Signal/Communication - Intermittent

Saturday,30,May,2015,16:29:20:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 55: Headlight Range Labels: 1T0-907-357.lbl

Control Module Part Number: 1T0 907 357

Component and/or Version: Dynamische LWR 0003

Software Coding: 0000004

Work Shop Code: WSC 01279 785 00200

VCID: 74EDF75B178523817A7-8021

1 Fault Found:

01312 - Powertrain Data Bus

014 - Defective - Intermittent

Radio, address 56, Stuck on "CAN init..." while buttons 02, 18, 1a, and 16 enable/disable, and radio in car repeatedly turns on and off. Eventually received error dialog "VCDS: Session Unreliable", "Too Many Communications Errors to Continue!"

Saturday,30,May,2015,16:32:06:15884

VCDS Version: Release 14.10.2 (x64)

www.Ross-Tech.com

Address 65: Tire Pressure Labels: 3C0-959-433-65.lbl

Control Module Part Number: 1K0 959 433 CT HW: 1K0 959 433 CT

Component and/or Version: RDK 0450

Software Coding: 0100101

Work Shop Code: WSC 01279 785 00200

VCID: 040DA79B472513014A7-8051

1 Fault Found:

00625 - Vehicle Speed Signal

008 - Implausible Signal - Intermittent

Freeze Frame:

Fault Status: 00101000

Fault Priority: 4

Fault Frequency: 1

Reset counter: 99

Mileage: 177484 km

Time Indication: 0

Date: 2000.00.00

Time: 12:06:42

|

|

|

|

Tue Oct 27, 2015

19:53

|

|

|

I bought the R32 knowing that with the mileage it had I should be expecting it to need the timing chain guides

and dual mass flywheel (DMF) replaced at any time. The timing chains on the VR6 are a lifetime part, but the

tensioners and guides are not. The chains themselves are inexpensive enough that most people go ahead and replace

them too, while they're in there. It is a substantial amount of work to get access to both the upper and lower

chains, in order to replace the guides and tensioners, and since the chains are on the PTO side of the engine,

if it's anywhere close to possibly needing the DMF replaced, that's the time to do it, since you'll need to

remove it to get access to the lower timing chain. Likewise, if you're in there doing the DMF it makes sense

to do the timing chains while you're in there. I started hearing the tell-tale worn DMF noises last winter, as

well as feeling the engine sometimes shake at idle (especially on cold starts). The DMF is two parts, with the

inner and outer parts being connected via strong springs, similar to a sprung clutch disc. The more worn the DMF

springs get, the more it is mechanically allowed to run out of true, throwing its balance off under certain conditions.

Catastrophic DMF failures have been known to lead to engine crank case and transmission bell housing damage. Folks

with the traditional manual transmissions have the option of reverting to the older style single mass flywheel, which

is not prone to these issues (worst case, you have it resurfaced if it has really been abused). The DMF, with it's

soft "sprung" connection, helps to eliminate jerkiness during sloppy or careless shifting. There is no real need for

the DMF with a regular manual transmission, but this is not the case with the DSG transmissions. In order for them

to function properly without becoming quickly damaged, it needs that extra bit of slop allowed by the DMF. The two

clutch packs used by the DSG are your typical wet clutches, inside the transmission, so there is no sprung clutch

disc to help dampen slight mismatches in engine and transmission speed during shifts.

Back to the story at hand, I found myself needing to do the DMF and knowing that the timing chains guides and

tensioners would be due soon as well. I went ahead and ordered everything I needed to replace the chains themselves

as well as all guides and tensioners, the DMF, and also oil and filter for the DSG transmission. Don't forget, as I did,

that to access the lower timing chain you will need to remove the rear main seal housing and so the rear main seal should

be replaced at the same time. I had to make a run to the dealership at the last minute, to pick up a new seal for a

not-so-great price. You will also need some of that good VW/Audi gasket maker for sealing around the timing chain covers,

in addition to the round seals for the variable valve timing connectors that go through the upper timing cover. Get

a new axle bolt, because you'll be removing the driver's side axle completely. Also, new subframe mounting bolts

(look at the updated ones sold by ECS Tuning, to replace the stock stretch bolts), and unless you want to pay for an

alignment after work is completed you'll want to get the special tools for maintaining the subframe-to-body alignment.

You don't need the special VW tools for clamping the coolant hoses shut, just get yourself a few pairs of regular coolant

hose clamps, or even use vise grips with something to protect the hoses from the serrated jaws. Bear in mind also, that

you will be removing the intake manifold and valve cover... so all of those gaskets are recommended unless they're pretty

new already. Lastly, don't forget the flywheel bolts (there are 10 of them) - they are not reusable and for the price versus how much work it

takes to get to them and the amount of damage that could result if they fail, why take the chance? If you don't already

have a set of the male 12 point sockets ("triple square" bits), you'll be needing to get them too. A cam locking tool

is absolutely necessary, but you do not need to buy the official one. A piece of steel plate, about 5/32" (4mm) thick

that is long enough to span the cylinder head front-to-back, and just a couple inches wide or so, is all you need. If you

don't have the right stuff laying around already, it's probably cheaper to get a small custom cut piece from SpeedyMetals.com

than to buy the official tool. Do yourself a favor and buy the special tool for removing the allen bolt going through the

transfer case output flange into the passenger side transmission output... more details about that below. Read on, and make

your own decision based on my foolhardy stubbornness rather than your own.

I'm not going to go through the entire procedure here, I would rather keep this confined to the highlights, and to information

that might help someone else get out of a bind (or avoid getting into one at all). The general idea here is: Remove the front subframe

(the best thing about electric power steering is that there are no messy power steering lines to disconnect), remove the intake manifold

and valve cover, remove the transfer case, remove the transmission, do all the timing chain stuff, then reassemble everything using the

new DMF. That's a drastic oversimplification, this is the second most involved car project I've done so far (the first being the engine

rebuild and swap in my old Mk2 Golf), so you will certainly want the official repair manual before starting this. I used AllData, and

ended up finding it to be a little lacking. During subsequent adventures, I have found AllData to be pretty poor when it comes to a lot

of the stuff on the R32... so I really can't recommend it anymore, for this application. If you're doing the DSG fluid change at the same

time, you'll also need a version of VAG-Com that works with CAN-bus cars.

I ordered my DMF from Bora Parts, it was by far the best price I could find. Unfortunately, their vendor sent me the wrong one and I didn't

realize it until I had the old one in my hands to compare it against. They were completely awesome about it though, and really went out of

their way to help. That was one set-back, not a whole lot I could have done about it. At the very least, I can pass on to you that make

sure your new DMF has a splined center rather than a smooth one, and make sure the outer diameter does not have locating pins sticking out

of it.

Before getting into the meat of it, you've got a lot miscellaneous stuff to remove... airbox and intake plumbing, wheels, brakes, driver's

side axle, and lots of suspension related stuff to disconnect. Try to stay organized by bagging and tagging loose parts and storing them in

a way you can keep track of the order they were removed. Here was my table-o-parts part way through:

The subframe came out easily enough, it isn't very heavy. Make sure to really properly torque down the locating pin special tools if

you're using them, and you may need to clean out the insides of the mounting bolt holes before inserting the tools to keep them from binding up.

A touch of thin oil (WD-40 or 3-in-1 or something) wouldn't hurt, too. Your tools may arrive with the tapered bodies installed onto the bolts

in the wrong orientation. Pay attention to the diagram in the repair manual, and remove and flip them over if necessary.

Here's a pic of the subframe being pulled out from under the car on a floor jack:

The transfer case doesn't have to be a royal nightmare. Just do yourself a favor and use the proper tool for that one bolt down in the passenger

side output flange. The underside of the bolt head is tapered, making it really stubborn to remove. And as you'll see, it's sunk about 11" deep

into the output shaft, inside a real small diameter bore, not much larger than the head of the bolt. The correct tool for this is just an allen

wrench with a whopping great extension. Let me tell you the story of my own self-made disaster, if you haven't already made up your mind about

using a suitable bespoke tool. Clever me thinks "Hey, it's just an allen bolt. I have a really long 3/8" drive extension, and my 3/8" to 1/4"

adapter is almost small enough to fit inside that bore... I'll just turn the OD of the adapter down on the lathe, then I'll be able to use my male

hex socket with an impact gun to zip that bolt right out of there." Sure. Right. Good idea. Fast forward a few minutes, and I have the 3/8" to

1/4" adapter turned down to fit in the bore, and I can see that the wall of the adapter is pretty thin in one spot... but I just think to myself

"... bah, it'll be fine. Worst case, if it splits open, I'll pull it out with my magnetic pickup tool and I'll be no worse off than when I started."

Uh-huh. Okay. So I get this hokey arrangement of really long 3/8" drive extension, modified adapter, and 1/4" drive hex bit down inside that bore,

get the hex bit seated firmly, and give the impact gun a quick burst. Immediately, there is no resistance to the impact gun. I withdraw the hokey

arrangement to find all the hokiness has remained down in that bore. I put the 3/8" drive extension back down it to get it to engage with the adapter

again, and no luck at all. The adapter had split open, of course. I went and grabbed my magnetic pickup tool and slid it down the bore until it

snapped onto my split adapter. Sort of. You see, I was now fighting three things... none of which had occurred to me when constructing the

"Hey, what's the worst that could happen?" scenario. Firstly, the diameter of my magnetic pickup tool was such that most of the actual magnet wasn't

actually touching the remaining rim on the backside of that modified adapter. Secondly, the surface area of rim at the back of that adapter was

almost non-existent. Thirdly, even if I had a magnet that would fit down into the 3/8" square hole in the back, the adapter was so firmly wedged into

place from the walls splitting open that no crappy pickup magnet was going to budge it.

I was now faced with making special tools to extract that mess, as well as making the proper tool that I should have just made in the first place.

After chewing myself out for several minutes, I came up with a plan. There was still some meat on that stuck adapter that could be drilled into

from the back. I would drill a very good hole of known size into the back of it, then on the end of a long rod I would turn

a plug to a size that would be a tight fit when driven into that hole. That should let me work the split adapter back out of the bore. Dear Lord,

PLEASE let this work better than my last hair-brained idea! Challenge #1: Drill a good round hole of known size. Well, twist drills generally suck

at making round holes of a known size. With good drills and the right approach, the results can be pretty good though. I broke out my good cobalt

steel machine length drills, and chose a number size that would be big enough to get some respectable surface area but still leave plenty of meat in

the adapter around the hole. Challenge #2: Make the drill bit reach the bottom of that long bore. I needed a drill extension. No problem, that's what

scrap stock and lathes are for. I would use a steel bar long enough to comfortably reach down the bore, and make a drill bit holder out of it. Challenge

#3: Keep the drill bit oriented and perfectly centered without being able to actually see down the bore. Also not a big deal - I would make the part of

my extension that holds the drill bit out of a larger diameter piece of stock, turned down to be an exact sliding fit within the bore, and press that

onto the end of the extension body. The rest was just some quick metal work. I used a length of 1/4" round steel for the extension body, and a short

length of larger diameter steel that I turned down to 0.001" smaller in diameter than the bore of the transfer case shaft. Actually I was shooting for

0.001" smaller but I actually was able to get it 0.0005" undersize, which was fantastic. I drilled the hole to receive the drill bit, using the actual

drill bit I'd be using, and done carefully that left a good lightly-snug fit. I reversed the drill holder, held in a collet, and drilled that end.

The 1/4" extension body was then chucked in a collet, and the very end turned down to be a press fit in the drill holder. The potential error in

concentricity would have been, at most, the sum of the runout of the two collets I used. Used properly even inexpensive collets should have less than

a thousandth, and mine are all Rivett and Hardinge that are old but haven't been abused. For this application, where I'd be using a hand drill, that

error didn't matter at all. Anyway, I drilled and tapped a set screw hole for holding the drill bit in place and then tried it out. I put some grease

on the drill bit to hang onto the metal chips. The bore does not open at all to the inside of the transfer case, but the fewer chips I had to fish out

with the magnet, the better. The drill bit holder was a beautiful fit in the bore, and the little bit of oil I used on the outside of it made it fit

like a piston, so I had to slowly push it in to let air escape. It doesn't get much better than that! The drilling went well, and I took care not to drill

too deep. I planned on making the puller plug from aluminum so failed attempts wouldn't ruin my carefully drilled hole, and I could drill it deeper to get

more grip. The hole was quite shallow, only about 1/16" deep not including the depth from the point of the drill (that is to say, there was about 1/6" of

straight walled hole before reaching the tapered bottom formed by the point of the drill). I quickly turned down some 1/2" diameter aluminum stock with

a plug at one end that would be a real tight fit in the hole. On the other end of the aluminum, I drilled and tapped a hole for bolt, for hammering on.

It drove into place pretty hard, and was a good enough fit that I had no problem wiggling the stuck adapter out of the bore. For your viewing pleasure, I

present the custom made extension drill (still covered in grease and metal chips) and aluminum plug with the broken adapter still stuck onto the end:

And finally, I could make the special tool I should have used in the first place. I took a length of 1/2" diameter steel and in the lathe drilled out one

end to a diameter about halfway between the distance across the flats and distance across the points of the allen key hex. I lopped off an allen wrench

that was the correct size with an abrasive cutoff tool, then on the bench grinder quickly ground a hollow into the cut off end so that the the outside points

and flats would make better cutting edges when being pressed into the steel rod. I just used a big ol' hammer to drive the hex key into the steel rod, it

ended up sinking in a little over 1/2". I then took a cheap 1/2" to 3/8" drive adapter, chucked it into the lathe, parted off the 3/8" square part, then

drilled the remainder of it through with a 1/2" diameter hole. The drilled out adapter was then welded onto the end of the steel rod holding the hex

key. Voila, a 1/2" drive super long allen socket:

I am happy to say, that tool worked like a charm. I'll reiterate that the bolt comes out harder than you'd expect, due to the head having that taper on its

underside. I imagine most people will opt to buy the special tool rather than make one... but either way, you will need something fairly strong. If you have

a long enough 1/4" drive extension then you'd probably be able to use it with a 1/4" allen socket, as long as you had a magnet handy to retrieve the socket if

it gets separated down in there. In this pic you can see the transfer case after removal. Isn't it the cutest little transfer case you've ever seen?

The intake manifold is a real hassle to remove on these cars. The manual says that the entire front clip must be disconnected and placed into "service"

position. That sounded like all kinds of work that I'd rather not do, so being the stubborn New Englander that I am, removed it without taking anything off the

front end at all. It's a tight squeeze, but it is possible. With everything clear out of the way, including removing the lift hook on the passenger side of

the engine and removing the bolts that attach the actuator for the variable length intake runners to the end of the manifold (the actuator will stay attached,

but you can rotate it around to clear the obstacles), the manifold will barely squeeze over to the passenger side, and come out where the airbox and everything

used to be. I'm not going to lie, it's a real pain removing the intake manifold bolts with the front clip in the way, and installing a couple of them is

no picnic either, but it can be done.

I used a floor jack and jack stand to support the engine when removing the subframe and transmission, rather than use a support fixture like the manual states.

Heads up, the DSG transmission is HEAVY. It weighs literally 3 times as much as an 020 transmission, so keep that in mind if you're not used to dealing with them.

There were no tricks to physically removing the transmission, it's just good old fashioned grunt work. Here's a pic of mine, right after removal:

With the transmission out of the way, the flywheel can be removed, and with that and the intake manifold and valve cover removed, the upper and lower timing covers

can be removed, to access the timing chains, tensioners, and guides. The lower chain drives the intermediate shaft from the crankshaft, and the upper chain drives

the intake and exhaust variable timing housings from the intermediate shaft. The variable timing housings are coupled to the camshafts and are electronically

controlled to advance and retard the cams relative to the chain. Because of the variable valve timing, great care must be taken to follow the correct procedure for

setting the cam timing. Again, you'll need to lock the cams in place - here is a pic of my cams locked in place using a piece of scrap 5/32" thick A2 steel plate I

had in my scrap box:

With the timing covers removed, you'll notice that the upper timing chain passes through the head gasket. When you attempt to remove the lower chain, you'll find that

there isn't quite enough slack in the chain to completely remove it, even with the tensioner removed. You can actually get it off by sliding out the intermediate shaft.

The alternative would be to remove the sprocket from the intermediate shaft, but that seems like an unecessary hassle, given that the entire intermediate shaft pulls

out freely (unless somebody has installed the retaining plate present on earlier versions of the VR6, that is). The intermediate shaft drives the oil pump, so there

is no need to reinstall it in a certain orientation but it can be tricky getting it to mesh back in with the oil pump when reinstalling. Be careful not to disturb or

damage the bearings when reinstalling the intermediate shaft. Here is a pic of the upper and lower timing covers removed:

The intermediate timing marks can be difficult to see properly, because there's not enough room for your head directly in front of it where you can see the marks without

any parallax error. There is a machined part of the casting behind the sprocket that forms a point, and that point has to line up with the point cast into one of the

holes in the sprocket. I used my camera phone to tell for sure when the marks were lined up, that worked really well. The next pic shows the marks misaligned, and the pic

after that shows them aligned correctly:

I think the engineers at Volkswagen must take some perverse pleasure in giving us ambiguous timing marks to use. Even going back to the earliest watercooled cars, identifying

the correct timing marks to use can be confusing even with the factory repair manual in hand. The 24 valve 3.2 VR6 is no exception to that. Even though the arrows engraved

on the variable timing control housings are clear and unambiguous, the features on the cylinder head casting to which they must be aligned are not so easy to identify, even when

looking at the diagrams. The next pic shows the intake timing marks lined up, and the following pic shows the exhaust timing marks lined up:

My last bit of advise is regarding the DMF. The 10 bolts for attaching it to the crankshaft should be tightened in a cross pattern. They are stretch bolts, so they get torqued

stages, up to a torque spec, then with an additional portion of a turn each. Since the crankshaft wants to spin around as you're torquing them, it's difficult to perform the final

sequence, and easy to lose track of which bolt is which in the sequence. To keep track of which bolt is which, I numbered them with permanent marker. Then, to perform the

final fraction of a turn on each one, I used an impact gun. I placed a mark on the head of each bolt, and a mark around the hole in the DMF for each bolt offset by the amount each

bolt needed to turn. The impact gun was carefully used to bring the marks into alignment. This pic shows the new DMF installed, and you can see my markings:

It was a lot of work getting everything back together, but taking my time paid off. She started up an ran beautifully. I had some suspension knocking during my first test drive

that turned out to be caused by a sway bar end link I hadn't tightened properly. So to recap, this is a really involved project that requires some special tools, the factory manual,

and a good amount of stubbornness and resourcefulness. All this work isn't for nothing... this is a very expensive job to have done at the dealership or specialist shop, so if

you're capable of doing it you can save a lot of money tackling it yourself. I put a couple of solid weekends into this, plus a couple of weeks of my spare time in the evenings after

work.

|

|

|

|

Sun Apr 05, 2015

19:14

|

|

|

Our Ford Flex had been having an occasional problem with the transmission slipping out of gear (engine revving, but no power),

and in each case my wife was driving and was able to continue after pulling over, shutting the car off, then starting it again.

No check engine light or anything helpful like that. After some research, it sounded like the likely culprit was the

transmission range sensor. This sensor is attached to the shift linkage, and gives feedback to the computer to indicate which

gear (or "range") is selected. Seems like a needless complication, and to make matters worse the Flex has it mounted inside

the transmission and the solenoid body and valve body need to be removed before the sensor can be replaced. I could not find

one single writeup or video or any pictures online, of anyone doing this themselves. So this seems to be the first post about

Ford Flex transmission range sensor DIY replacement. Be forewarned, this one is not for the novice. If you don't have the

factory repair manual, or an alldata subscription, do not bother attempting this. If you have plenty of shadetree wrench-turning

experience, are patient, and take your time, you'll do fine. There is an easy electrical test you can do to determine whether

the transmission range sensor is faulty, in fact Ford issued a TSB about it.

Here is a pic of the new sensor assembly. I couldn't find any pictures of the sensor assembly online that definitively, absolutely

stated that this actual sensor assembly was for the Ford Flex. Well here it is. It looks nothing like what I expected:

The writeup that follows is NOT a complete procedure for you to follow, without the aid of proper documentation. I am going to

mention a few specific things that may help you, but you NEED to have a proper procedure to follow... I am using alldata for

both our Flex and my R32. To start with, the basic disassembly of components in the engine bay, to gain access to the front

of the transmission:

So you can see what sort of room there is to work with. It's a bit tight, but reasonable. You will have to move the coolant

hoses up and out of the way in order to remove the dipstick funnel... it needs to be rotated 90 degrees and then pulled straight

out:

Even though the official procedure has you completely remove the upper transmission oil line, I disconnected the end going up to

the top of the transmission, and that was sufficient for me. It did make access to a couple of the bolts a bit tricky though.

The shift cable needs to be disconnected at some point, so that you can remove the lever from the top of the transmission range

sensor (part of the sensor assembly protrudes through the top of the transmission, and this is what the lever attaches to).

Before the sensor assembly can be removed, the solenoid body and valve body need to be removed. The solenoid body is attached

with bolts of varying lengths, so it's important to keep track of them. It's impossible to tell which bolts are holding the valve

body itself together, versus those that are holding it into the transmission, so the official procedure will again be necessary

for this.

You will need to pry out the retaining pin that is holding the sensor assembly in place. You won't be able to see it without a mirror,

you should be able to feel the head of it with your fingers. There isn't much to pry against, just a very small boss around the hole.

A screwdriver won't work, unless you bend and grind it to fit. I made my own little pry bar to fit, and it was still pretty tough

going. Eventually I got it worked loose and could finally see what the critter looks like. Here are pics of the little tool I used,

and the pin itself:

When re-installing the pin (the official procedure says to install a new one, but I re-used mine), you can just use a short drift punch

and the broadside of a hammer to drive it back into place.

Follow the official procedure for disengaging the sensor assembly from the transmission housing and the parking pawl. This is your

final warning, do NOT attempt this without referring to the official procedure. If the parking pawl lever gets pulled out a bit too

far, you will have to remove your transmission from the car and disassemble it to reinstall the lever. Take time to get yourself calm

and collected before this step. It's easy to get into a state where your patience has worn thin, and you're left with the parts in a

position where you cannot let go of them without risk of the parking pawl rod pulling loose. I will say that it's not quite as easy

as the official procedure makes it sound. You'll need to be patient and carefully work at it.

With the sensor assembly successfully removed, you should be staring at a pretty empty cavity in the front of the transmission.

In this picture here, everything has been removed, and the end of the parking pawl is just visible inside the orange circle:

There were no real tricks during reassembly, again just take your time and collect yourself before attaching the parking pawl to the new

sensor and getting it into place. Pay attention to the torque specs and tightening sequences for all of the bolts you need to

reinstall. Reassembly took me about a quarter of the time it took to disassemble everything. Altogether, I spent a solid day on it...

from about 9am to about 5:30pm. First impressions after test driving are favorable. There used to be a strange noise shifting into 4th

gear, and I could never quite decide whether it sounded more like a heat shield rattle or the muted sound of gears not engaging properly.

At any rate, the noise is gone now, and I expect that there will be no more problems with it slipping out of gear.

|

|

|

|

Sun Apr 05, 2015

15:18

|

|

|

Our Flex has had a noise in the rear for some time now. When we bought it, used, a couple years ago, it

had a bit of a noise and it always sounded like tire noise to me. This year we replaced the tires... and

if you'll allow me to go off on a bit of a tangent, I ordered them from the Tire Rack, as usual. I ended

up going with Continental TrueContact SL. They weren't cheap, but they were not as expensive as many of

the good sounding alternatives. My primary demands from the tires were good tread life, and a quiet ride.

The Flex was engineered to be a quiet, comfortable ride... I did not want noisy tires to spoil that. Back

on topic, after replacing the tires, the noise was still present... and I was quite surprised by that.

At this point, given the way that the noise changed (got better/worse) as one side of the vehicle or the

other was loaded up during cornering, it really was behaving like a bad wheel bearing... except it didn't

sound like any wheel bearing noise I had ever heard. It was almost like the sound of a baseball card stuck

in your bicycle wheel spokes, but very deep and rumbling. Some online research pretty quickly revealed

that Flexs are prone to wheel bearing problems. The forums are full of people having to replace noisy

wheel bearings within 20,000 miles. Some of the noises described sounded similar to what I was hearing.

Our Flex has 117,000 miles so I can't really complain about some bad bearings at this point. I ordered a

pair of rear wheel bearings (the rears and fronts are actually the same) from RockAuto.com, and one of

them was completely seized, upon arrival. Not impressive quality there. RockAuto are wonderful about returns

and I had a replacement in a flash.

From what I had read about the procedure for removing the rear wheel bearings, they were held in place by

large Torx bolts (I believe I saw T60 mentioned somewhere), but that the bolts were nearly inaccessible due

to the ABS sensor rings being in the way. The thing to do, apparently, is to press a torx bit out of its

socket, and grind down the rear of it to clear the sensor rings, then use a wrench on the remaining flats

of the torx bit. Well I'm happy to say that it was not necessary on our Flex. Our wheel bearings were

held in place with regular hex bolts, and there are no rear ABS rings in the way. Our wheel hubs have the

ABS sensors mounted into them, but I've no idea what they're picking up on because I see no trace of a

sensor ring or trigger wheel. This was still not exactly an easy job, because the car has spent 100,000

miles in New England, and the wheel hubs are aluminum, the bearing housings were corroded in place like

you wouldn't believe (or maybe you would, if you live up this way).

Before you attempt this job, verify whether you have torx bolts or hex bolts, and whether you have ABS sensor

rings in the way of them. Also make sure you have a socket large enough to fit the axle nut, and deep

enough to clear the threaded axle coming through the nut. If you're an amateur machinist, you may find

yourself tempted to clearance the bottom of a regular socket... don't bother, I tried that and it just

won't work out. You'll need a deep 32mm socket... 1 1/4" will actually be a closer fit, and that's what

I ended up using. Even if you have a deep socket, you need to make sure that the hex flats seat fully all

the way up onto the nut. The nuts are fairly shallow, and most sockets (especially cheap ones) have a

lot of relief leading into the internal hex flats. I took my deep 1 1/4" socket, chucked it into my lathe,

and faced the hex end to remove all the relief. That ended up being about 3/16". Without doing this, the

socket barely gripped the nut. Here is my deep socket, after being turned on the lathe, so you can see

what I mean:

With the axle nut removed, and the brake disc, caliper, and carrier bracket out of the way, the bearing assembly

can be removed... in theory. I ended up using a small puller (it was just barely big enough) to put as much

force as I could against the bearing housing, and then I heated up the wheel hub (or "knuckle", or whatever

you want to call it) with a torch. I also used some good penetrating oil. Be careful of those rubber bushings

that are all around, and definitely get your ABS sensor out of the way first. One side only took a couple of

minutes of heating before it popped free. The other side took much more persuasion, I ended up setting up

the torch with the trigger locked in, pointed at the bottom of the housing, then sat and watched it while I

enjoyed a beverage. About 7 minutes later, *BANG*, the bearing housing popped free. Here are a couple of pics

showing the puller arrangement I used... nothing fancy:

And a couple of pics showing the corrosion around the bearing housings, the first one is just after the bearing

assembly popped loose, and the second one shows the wheel hub with the bearing housing removed, and here you can

really see how the corrosion has built up. Be sure to clean up the surfaces really well before installing the new

bearings. The new bearings should be a very easy fit within the hubs.

We now have a nice, quiet Flex!

|

|

|

|

Thu May 15, 2014

18:35

|

|

|

I had purchased a VF Engineering "pendulum" transmission mount from the good people at ECS Tuning a while back,

and I finally felt good enough (after a recent neck injury) to install it. The 3.2 VR6 in the R32 makes a bunch

of torque, so those factory rubber mounts take a real beating. Soft and unpredictable throttle response, lurchy

downshifts, and less-than-crisp upshifts can all result from this. I don't know what the DSG R32s felt like

when they were new, but I know what mine (with 96,000 miles on it) felt like when I got it. I had chalked up

the strange throttle response to it being drive-by-wire, but the lurchy downshifts were especially annoying.

The VF Engineering mount, shown below, uses a polyurethane insert to fill up the voids in the factory rubber

mount on the chassis side, to increase rigidity. I bought the full mount, which includes the aluminum

"pendulum" parts, fitted with polyurethane bushings:

It was a breeze to install - it only took about an hour, and that was with the kids "helping". To install

the poly insert, I greased it up with a little bit of petroleum jelly and tapped it into place with a rubber

mallet. If you're just doing this one mount, supporting the engine isn't necessary (but it can help the bolts

come out a bit easier), this mount only keeps the motor from rocking back and forth on the other remaining

mounts. I needed to use a jack to crowd the engine just a bit to get the holes to line up when installing

the new mount.

The mount made a very noticeable difference. The throttle response is definitely sharper, downshifts are

amazingly good now, and upshifts are a little bit more crisp. I noticed absolutely no difference in

vibrations or harshness coming through the chassis.

|

|

|

|

Tue May 13, 2014

17:09

|

|

|

I had been keeping my eyes peeled for a cheap set of wheels for the R32, that I could swap the winter tires onto

and then put the summers on the factory wheels. I had a tough time finding anything that fit the bill, and for

under my budget for used wheels I managed to score a set of brand new Alzors from ECS Tuning. They were on

clearance, and I liked the look well enough (they're replicas of wheels found on the Audi S8). The quality is OK,

though the center caps are pretty poor. I used Siemens tire pressure sensors and didn't have any trouble

with them at all. You just need to keep in mind that the factory tire pressure is a lot higher than you might

think - 42psi both front and back. Get it much below that and you'll get the TPMS warning light.

Here she is, with the summer wheels and after a fresh coat of wax:

After waxing it by hand, I know where all the little imperfections are. There are a few rust spots starting that

I need to nip in the bud (the car is 6 years old, and from Maine, so I'm not too surprised), and the rear bumper

has been repainted... the paint was very well done and I never would have noticed except I can see through a couple

of scratches that the color underneath is deep blue pearl.

|

|

|

|

|

|

A1 parts for sale:

|

Item:

Item: Intake air pre-heat hose (from exhaust manifold shroud to air box), for Scirocco 2 (1982+)

Condition: New

$12

|

|

|

|

A2 parts for sale:

|

Item:

Item: GTI dual-round grille with inner lights, bulbs, and lower trim strip

Condition: Used, lower trim strip is weathered.

$35

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

Item:

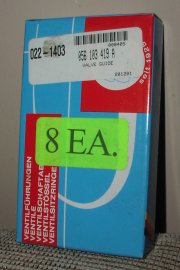

Item: 8 (eight) valve guides, German, standard size, for 8 valve head

Condition: New

$24

Item:

Item: Wheel cylinder (for rear drums, obviously), 2 available.

Condition: New

$12 ea.

|

|

|

|

A3 parts for sale:

|

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

|

|

|

|

A4 parts for sale:

|

Item:

Item: OEM Water pump, ALH engines

Condition: Used, 130,000 miles

$20

|

|

|

|