|

Sat Mar 17, 2007

11:09

|

|

|

A fellow Vortexer was parting out a 1998 VR6 GTI, so I made a deal to buy the

front and rear black leather seats along with the smoked rear tail lights.

Claire and I swapped out the seats this afternoon, and then Claire swapped

the tail lights. All we need now is a set of black leather door panels that

will fit. I did get the GTI door panels thrown in with the seats, but GTIs

are 2 doors and our Golf is a 4 door.

Here is Virginia with the smoked tail lights:

And here is the interior with the new seats installed:

|

|

|

|

Sun Feb 04, 2007

16:51

|

|

|

Last summer I

replaced the main bearings in our 1996 Golf (her name is Virginia), and I really should have done the

rod bearings at the same time. I just got back from my trip to Australia last week,

and was welcomed with single digit temperatures. In that kind of cold, I noticed

Virginia was awfully noisy until the engine warmed up, and it sounded like it could possibly

be rod knock. The rod bearings are pretty easy to replace, so I decided to do it - plus, I

already had the new bearings sitting around somewhere.

The job went real smooth, and even though the old bearings weren't worn quite as much as I

expected, they were still pretty trashed. Lots of pitting and scoring in all of them. The

upper halves of the bearing shells showed far more wear than the lower halves.

Here are some pics (click them for larger views):

And here is a picture of the tiny bits of plastic I found in the bottom of the oil pan. I found these

last time, too. The black pieces are hardened gasket maker material, and I think that the reddish brown

pieces are from a broken dipstick tube (you VW owners out there know how often those things break).

There's nothing else I can think of made of that color plastic that could get into the oil. (click

for a larger view)

|

|

|

|

Sun Mar 12, 2006

22:02

|

|

|

Last weekend we took a trip to visit friends in Keene, which involved driving down

a particular stretch of Route 101 with a speed limit of 65mph. Traffic flow along

that section of road is pretty much 80mph. We were in our 1996 Golf, which currently

has a very short 5th gear installed - so 80mph is well over 4000rpm. After about

20 minutes of cruising with the engine at higher rpms, I noticed that the oil

pressure light started to come on every time we had to come to a stop and let the

engine idle. I had noticed for a while that the engine was starting to develop a

pretty nasty sounding knock (not like a knock caused by cheap gas or incorrect

ignition timing) and it seemed to be getting slowly worse. During this trip, it

was bad enough so that the motor pretty much sounded like a diesel at higher

rpms under light to medium load. Needless to say, I took it pretty easy on the poor

thing after that.

Now, poor oil pressure only at idle is often a sign that the main bearings are

getting worn beyond their allowable tolerances (or that they are badly scored). A worn or malfunctioning oil

pump is also a likely candidate. Our 96 Golf only has 125,000 miles on it, so

I was surprised to see this happening at all. The 96 and later ABA engines, though,

use lesser quality internals - so I wasn't going to rule out main bearing wear

without doing some checking. I talked briefly to Klaus and Wolfgang over at Atlantic

Imported Auto Supply about this, and they informed me of a fairly common problem

on these ABA engines. Apparently, the plastic oil baffle surrounding the pickup

tube for the oil pump is notorious for cracking and breaking, which can cause

small bits of that hard plastic to clog the screen at the end of the pickup

tube. They suggested that I pay close attention to that.

If my only symptom were the oil pressure (without the knocking and rapping), then

I would have assumed an oil pump problem... but the noise really made worry that

the main bearings were in tough shape. The only way to really tell is to tear into

the bottom of the engine block and investigate. My dad was in town, visiting for the

weekend, so we both spent Saturday doing a little bit of open-heart surgery on that

ABA motor in the 96 Golf.

The oil pump, main bearings, and lower rod bearings can all be accessed by removing

the oil pan. On these engines, the oil pan is quite easy to remove because there

are no exhaust pieces or subframes in the way. Behold:

You'll definitely want to drain the oil first:

All of the bolts holding the oil pan into place are easy to get to, except for the

two closest the transmission - those 2 can only be accessed by removing that small

aluminum plate covering the very bottom of the bell housing. That plate is very easy

to remove and once it's out of the way you get to those 2 tricky bolts by using a

"wobble" extension (a socket extension with the end formed so that the socket will

wobble just a few degrees in any direction). On the ABA engines (and some others)

you can use either a socket or a torx bit to remove the bolts. They use nice bolts

that are 6 point on the outside, and torx (star) on the inside. So no need to panic

if some of them are stripped out! Oil pan bolts being removed:

Here is a closeup of the head of one of the oil pan bolts:

Even after all the bolts are removed, oil pans can be a pain to break loose. The gasket

material often causes it to stick, but enough persistence will get it done. The oil pump

will be in plain sight, staring you in the face once the oil pan is removed. The two larger

bolts going up through the bottom of the pump body are the ones that fasten it to the engine

block - remove those, and it will slide right out. Do not try to remove that plastic

baffle around the pickup tube unless you absolutely have to. It's quite difficult to remove

without cracking the clips that hold it in place. Here is a view of the bottom of the oil

pump and pickup tube/baffle.

And here is a view of the top of the pump, showing the input shaft and the teeth of the pump

gears (which actually pump the oil):

If you look closely at the picture showing the pickup tube, you can see a couple of dark flecks

caught in the screen. We also found pieces of old gasket material in the oil pan. If enough of

that junk got sucked up against the pickup tube screen, that could really inhibit oil flow and

cause poor pressure... however, I couldn't really see that being the problem in this particular

case (where oil pressure rises again as the engine rpms are raised slightly). It seems like

a blockage against the screen would keep restricting oil flow through all engine speeds, until

the blockage had a chance to fall back away from the screen. Here is the inside of the oil pan

with a little bit of oil pooled inside - even though there is a lot of junk floating around in

it, you really can't see it in the picture:

The plastic pickup tube baffle showed no signs of being cracked or broken, and we could find

no trace of that hard, black plastic in the oil. Since the oil pump was out anyway, I decided

to check it out using the procedure from the Bentley book ( the VW shop manual),

which involves measuring the backlash and the lateral play of the pump gears. It all checked

out - the pump had minimal (if any) wear. At this point, I was excited to measure the main

bearing tolerances. The main bearing caps can be seen clearly with the oil pan and oil pump

removed, as seen here:

The bearing shells farthest away from the oil pump will normally exhibit the most wear, so

we started by measuring the clearance of the #2 bearing (#1 bearing cap is a little more

difficult to remove - more on that in a moment). Plastigage is used to measure the bearing

clearance - it's just a thin strip of plastic that gets installed, sideways, between the

crank journal and the wear surface of the bearing shell. When the bearing cap is torqued down,

the plastic gets squashed. The bearing cap is then removed again, and the width of what remains

of the plastic strip is used to judge the clearance. Here is the #2 crank journal, with residue

from the plastigage still visible:

And here is the #2 bearing cap with the bearing shell still showing the plastigage:

Even though the wear was still within spec, there was visible scoring that went well down

into the copper layer of the bearing.

The #1 main bearing cap is tricky, because the heads of the bolts are so close to the plate that

covers the front main seal. The space is so tight that a socket will not fit around the bolt head.

An open-end wrench can be used (barely), but that is not recommended (you run the risk of rounding

off the bolt heads). The #5 bearing cap is even worse to get to - not only is it very close against

the plate for the rear main seal, but it's also right up against the toothed wheel that triggers

the crankshaft position sensor. The only way to remove #5 without splitting the engine and transmission

and removing the clutch and rear main seal plate is to use a socket with very thin walls. A thin

walled socket is also really the only good option for the #1 cap. My dad has a real knack for hacking

together special tools and modifying tools for special purposes, so he butchered one of my 1/2" drive

17mm sockets on the bench grinder, and we ended up with a magnificent thin-walled socket:

That couldn't have worked any better for those stubborn #1 and #5 bearing caps. We plastigaged the

#1 bearing and found it to be a little more worn than #2, although still within spec. That scoring

on #2 worried me, so I decided it was worth the little extra effort to change the main bearings

while we had everything apart. #4 was also scored (even worse than #2), and #5 turned out to be

the most worn (surprising, as it's closest to the oil pump). We didn't bother plastigaging #5, since

I had already made up my mind I was replacing all of them. Here is the very strange thing I found, though.

The ABA main bearings are each made up of 2 bearing shell "halves". The upper halves all have oil

passageways in them, and all of the lower shells are solid... except for #3. #3 has the

grooved shells both top and bottom. This is clearly stated in the Bentley manual. The lower shell

of the #3 bearing that I removed from this engine was not grooved - it was solid. I have

no idea why.

The trickiest part was removing and reinstalling the upper shells (between the crank journals and

engine block), but we managed. By the time the sun started to set, I was done installing the main

bearing caps, oil pump, and oil pan. After re-tensioning the timing belt and adjusting the power

steering belt tension (it was getting kind of sloppy), we were ready to fire it up. We started it

and let it run for a few seconds, and the oil pressure light was on constantly, regardless of

engine rpm. We figured it was just the oil pump being dry, and since we had used plenty of assembly

lube when installing the new bearings, we gave it another 30 seconds or so of running to try and

build some pressure. No luck. You know the kind of tricks your mind plays when things like this

don't go like you expect - you start to backtrace and think of anything that you could have done wrong.

What a lousy feeling. Everything had gone very well up until this point. Finally, we removed the

ignition distributor and rigged up a device to drive the oil pump using an electric drill. After

lots and lots of spinning, we seemed to have resistance in the pump again (it felt like it was drawing

oil). So we reinstalled the distributor and gave it another try... and success! We had oil pressure

and the motor sounded great - no more ugly rapping noises. The Golf has made quite a few small trips

since then, and it just runs great. I'm happy.

|

|

|

|

Sun Jan 08, 2006

10:32

|

|

|

A few days before Claire and I went down south to visit relatives

we had a very cold morning. It was right around 0 degrees

Fahrenheit. Our 96 Golf had always seemed to be harder to start

in very cold weather, and this particular morning it just would

not start after several attempts. When we finally did get it

started, it ran funny and the check engine light was on. At that

point, I didn't have time to look into it before we left for our

trip, so I left it until we got back. When we got back and I

hooked the car up to my laptop running

vagcom, this is what I found for a code stored in the ECU:

VAG-COM Version: Release 512.1-UD

Control Module Part Number: 037 906 259

Component and/or Version: MOTRONIC M5.9 HS V08

Software Coding: 00000

Work Shop Code: WSC 09446

1 Fault Found:

17988 - Throttle Actuator (Bank 1): Malfunction

P1580 - 35-10 - - - Intermittent

Seeing this made a lot of sense to me, because I have heard that

the electronic throttle actuators used in OBD-II Volkswagens are

prone to sticking and jamming during colder weather. I cleared

the code and it hasn't returned yet, although I expect that it

would be a problem again once the temperature drops. I hope that

some cleaning and silicone or white lithium grease will do the

trick to keep this from becoming a problem again.

|

|

|

|

Wed Nov 30, 2005

19:42

|

|

|

Our new Golf has been on the road for close to a month now,

and all is well. One thing I have noticed about the OBD-II

A3 Volkswagens is how slowly the engine RPMs drop between

gear changes. The OBD-I VWs have a small hydraulic device

on the throttle body that causes the throttle valve to

close slowly, achieving nearly the same effect. I believe

this is done to make the cars easier to drive. It allows

the driver to make easy, relaxed shifts without jerkiness

during clutch engagement. If the RPMs drop quickly, then

you must either shift quickly or quickly raise the engine

RPMs again as you re-engage the clutch in order to avoid

an ugly mismatch that can cause the car to buck or jerk.

Anyway, the reason I mention it is because the OBD-I cars

can be made to behave more naturally by removing that

small hydraulic device. The OBD-II A3s, however, appear

to behave this way due to the program in the ECU, and so

only an ECU update will get rid of this annoying trait.

All in all, she's a great little car that we are very

happy with.

|

|

|

|

Thu Nov 03, 2005

19:54

|

|

|

The black Golf had a state inspection appointment for Tuesday

of this week (that was November 1), so my plan was to drop it

off at the garage (Car Works) after dark on Monday. That would

lessen the chance of being pulled over for driving an uninspected

vehicle. My dad offered to follow me to the garage and give

me a ride back. Anyway, we went to start the Golf Monday

evening, and the battery was weak enough so that the starter

wouldn't crank. Kind of a pain, but no big deal - we jump-started

the car and drove down Route 125 to Car Works. When we got there,

I opened the door to get out of the car, and the alarm started

going off! The factory VW alarm simply blares the horn over and

over - the sound slices right through you. The normal way to

turn off the alarm is to insert the key into a door lock, and

turn it. I was frantically unlocking and locking doors to

shut the thing up, to no avail. The alarm simply would not

deactivate. By this time everyone at the shop was wondering

what the heck was going on outside. I had to run inside

and borrow a wrench so that I could disconnect the battery.

We spent a good 30 minutes there in the parking lot trying to

figure out what the heck was going on - the alarm goes off when

the battery is disconnected then reconnected (that's normal

behavior for VW alarms), but we had no way to turn it off.

I will spare you the

painfully long version of the story, but we finally managed

to get me into the driver's seat of the car, with the alarm

deactivated, so that I could drive it back to the house (the

car won't start if the alarm is active). After hours of

investigation without getting much of anywhere, we started to get

desparate and were checking everything that was even remotely

related to the alarm and central locking systems (not only

was the alarm acting up, but the central lock function seemed to

stop working as well). This car has the vacuum pump for the

central locking system located in the same housing as the

central lock control module. We tested the vacuum pump to

see if it was working, and it was dead as a doornail. Just

for the heck of it, and because the central locking system

is sort of related to the alarm system, we decided to see

what would happen with the central lock control module and

pump disconnected. Sure enough, the alarm behaved normally

again. Going back to the central lock module, my dad pried

the cover off the box, and some water poured out. The module

itself is just a small circuit board, and it was extremely

corroded and stank of burnt electronics. We got the car back

to the garage around 11:00pm.

I got a call on Tuesday from Car Works, saying that they

didn't like the amount of play in the front strut mounts.

I had replaced the bearings in the mounts, but not the rubber

bushing that takes up the space between the bearing and

the body of the car. So I took the car back that night,

spent a couple of hours replacing those bushings, and

the next morning I made arrangments to drop the car off

again. It is now back at the shop, waiting for a sticker.

|

|

|

|

Sat Oct 22, 2005

20:00

|

|

|

At long last, our "new" Golf is ready for state inspection. Today I replaced one of the

turn signal bulbs, a front corner marker bulb, both rear license plate bulbs, and one

tail light bulb. The brakes are all taken care of now, too. The parking brake cables

needed a lot of adjustment - that's kind of a pain because the rear section of the center

console has to be removed in order to get to the cable adjusters behind the base of

the parking brake lever. I had thought that the brakes would need to be bled, but

once the parking brake was adjusted, the brake pedal felt nice and firm.

So, that's it. That's all she should need to pass inspection. Since purchasing the car,

I have done the following work to it: New Neuspeed stainless steel cat-back exhaust system,

new master cylinder, new braided stainless steel brake lines, new front strut inserts,

new upper strut mounts, new rear wheel cylinders, new upstream oxygen sensor, new mass

airflow sensor, realigned front doors, adjusted parking brake, replaced a bunch of

exterior light bulbs. Looking back on it, that's quite a bit! Including the $1000 that

I paid for the car itself, I think I have just over $2000 into it - and that's including

the stainless exhaust sytem, which was almost $600 by itself. I could have gone for a

plain aluminized exhaust system for around $200, but I really wanted a high quality

stainless system. In this part of the country aluminized exhausts just dont' last

very long, and I don't enjoy doing exhaust work. At any rate, she is one *sweet* Golf

for just a couple grand.

I now need to make an appointment at Car Works (our local VW/Volvo specialists) for an

inspection, and an alignment (because I had the front suspension apart). I think it

should pass, but you never know.

|

|

|

|

Wed Oct 19, 2005

18:42

|

|

|

I meant to post this yesterday, but didn't get a chance. The

front doors on the black Golf are now aligned so that they open

and shut correctly without rubbing against neighboring body parts.

It really was kind of a pain, but well worth the effort. The doors

had to be completely removed in order to access the torx bolts

that hold the hinges to the body. The hinges have elongated

holes, which allows for adjustment.

|

|

|

|

Sun Oct 16, 2005

13:30

|

|

|

This morning I replaced the MAF (mass airflow sensor, or "air mass sensor" as VW calls it) in the

black Golf. I replaced it with a remanufactured sensor that I purchased from

Impex. I don't know what

"remanufactured" means with these things, but it looks brand new to me. You can get the reman sensor

for roughly $70, versues nearly $300 for the new.

Once the sensor was replaced, it was once again time to run through the tedious procedures for setting

the readiness codes, using the vag-com

software. There are portions that require the car to be driven under certain conditions while at the

same time examining the feedback from the vag-com application. It would be very difficult and incredibly

dangerous to attempt that on your own; fortunately, my dad was around to ride shotgun and keep an eye

on the laptop while I drove. I am always worried that stuff won't work, so imagine my delight when

when we finished all 20 procedures and saw the following screen, telling us that the readiness codes

are now set:

|

|

|

|

Sat Aug 13, 2005

21:52

|

|

|

It's been a while since my last post. You may have noticed there is now

a link over to the left to get an RSS feed. I

doubt anybody will subscribe, but hey - it's there if you want it.

So, the new oxygen sensor

is now installed. Since the purpose of this blog is to document my mechanic-ing, here is a little writeup

outlining what was involved.

Here is the target of our operation, the old oxygen sensor. This is the upstream (or forward) oxygen

sensor so it lives, as you see here, threaded into the rear of the downpipe (just ahead of the catalytic

converter).

Here is a point-of-view that I'm all too familiar with.

Okay, step one is to unplug the electrical connector coming from the oxygen sensor. In this case,

the plugs for both oxygen sensors meet their mating plugs in the back of the engine bay, toward the side

where the airbox is mounted. The engine mount in that rear corner has a small bracket mounted to it

that the oxygen sensor plugs snap into, to keep them from floating around inside the engine compartment.

These two pictures are looking down past the air intake at the plug for the upstream oxygen sensor, disconnected

from it's mating plug. You can't see it, but just behind my hand in the second picture there is a brown

plug, which is the connector for the rear (downstream) oxygen sensor.

With the electrical connector unplugged, and the clips/zip-ties removed from from the wire, the sensor

itself can now be removed from the downpipe. In the first picture below, you can see a special oxygen

sensor socket slid over the sensor. Unless you're willing to cut the wire off the sensor, you need more

than just a really deep socket - you need one of these, which has a channel cut into it that lets the wire

get out of the way. Of course, you can also use an open-ended wrench if you happen to have one the right

size. It can sometimes be a real struggle to remove an old oxygen sensor. I usually have good luck

letting the car run for several minutes, and then squirting some penetrating oil (like PB Blaster or Aero Kroil)

around the mating surfaces. In this particular case, it worked quite well - very little effort was required

to remove the old sensor.

Here is the new sensor (Bosch, of course) - I recommend OEM for these things because I've heard too many

stories of people using aftermarket sensors that don't respond as quickly. For older cars, it's probably

no big deal, but for anything 1996 (OBD-II) or newer, that could be a problem. This Bosch sensor even

came with anti-seize compound on the threads - how nice is that!

Here is the new sensor being installed.

With the new sensor installed, I fired up the vag-com software on the laptop again to take a look at things.

As expected, it showed that the upstream oxygen sensor was now perfectly within spec all of the time. Unfortunately,

I continued to get "multi-trim fuel bank too rich" DTCs when trying to set the readiness codes. Below is a

picture of the Go Mango laptop running the vag-com software. Notice the USB-to-OBD adapter running from the

laptop to the diagnostic port in the dashboard of the Golf.

I've been doing some research about this multi-trim message, and somewhere in the VW Vortex

I found this really handy posting on the ross-tech website:

http://www.ross-tech.com/vag-com/cars/fuel-trim.html.

It looks like I need to take a closer look at my Mass Airflow Sensor. I'm not getting any codes that indicate a

MAF problem, but it's worth checking at this point.

|

|

|

|

Wed Aug 03, 2005

23:29

|

|

|

Shift linkage is

now taken care of. I removed the bolts holding the bracket to the steering rack, chased the

threads with a tap, and reinstalled the bolts using some red loctite.

In other news, the new oxygen sensor

for the black Golf arrived today. Sweet.

|

|

|

|

Sun Jul 31, 2005

11:44

|

|

|

I found an OE upstream oxygen sensor for the 96 Golf at Autohaus

Arizona for $72.92 so I went ahead and ordered it. 2 day UPS delivery was only $9.31 extra -

so even with fast shipping it was cheaper than the next best price I found. Sweet.

|

|

|

|

Fri Jul 29, 2005

22:32

|

|

|

So, last night I took a stab at setting the readiness codes on

our A3 Golf. After

replacing the cracked ignition coil, I wanted to give it a try to see if that was

the cause of my DTC indicating a rich-running condition. I am still getting that

same DTC part-way through the readiness procedure, so now I am leaning toward

the upstream oxygen sensor as the culprit. The duty cycle for the upstream sensor

is intermittently out of spec, I have noticed.

I meant to post this last night, but I just didn't have the time.

|

|

|

|

Mon Jul 25, 2005

21:31

|

|

|

This evening my dad stopped by with a spare ignition coil to try on the

A3 Golf. Once the old coil was removed, it didn't take

much looking to see that it was badly cracked. It still had some throttle

hesitation after swapping the coil, but in the course of fiddling with

things, we ended up removing the connector from the throttle position

sensor and then reconnecting it... and then it ran just fine. I think

the connector may not have been fully seated.

So now I'm really eager to hook the laptop back up and see if I can get

those readiness codes all set. More news tomorrow, I'm sure.

|

|

|

|

Sat Jul 23, 2005

23:12

|

|

|

Sat Jul 23, 2005

11:41

|

|

|

This is another background post, regarding our "new" 1996 Golf. This black beauty came from LaPlata, MD

(just a few miles from the Maryland/Virginia border), the previous owner was getting rid of it for a song

because it had issues he didn't want to deal with. Those issues were, primarily, brake fluid leak, wheel bearing

noise, and of course the "check engine" light was on. My father and I have done crazier things than drive

to southern Maryland, buy a car, and tow it back all in the same day... I just can't remember any offhand.

We rolled into LaPlata a little before 6:00am after driving all night, and by 9-ish we were back on the

road with the Golf in tow. Before too long, we had an incident with a truck driver honking crazily at us

and trying to catch our attention with excited gestures. So we pulled onto the side of the highway and

inspected things - turned out the rear drivers' side wheel bearing was loose. We limped to the next exit, found an

empty parking lot, removed the wheel, and tightened the bearing a whole bunch. That would be the source

of the bearing noise the previous owner was complaining about. I think when that bearing was installed one

(or both) of the outer races didn't get pressed completely into place, and as the car was driven they

slowly seated themselves, leading to excessive play. At any rate, we completed the rest of the journey without

incident.

I'll post pics of the car later, but she's definitely a looker - especially for a 4 door. No rust (gotta love

those southern cars), good original paint, and fewer-than-usual dings.

The problem with the brakes, which the previous owner had supposed was a bad master cylinder, turned out to be an external fluid leak

at the passenger side rear wheel cylinder. It was leaking so badly that brake fluid peed out everywhere

when I removed the drum. The cylinder on the driver side was beginning to leak as well. I replaced both

rear wheel cylinders, as well as the master cylinder (I had already ordered it, and the old one will come

in handy the next time I need to do a big brake conversion on a Rabbit) and both of the flexible, rubber

brakelines up front that attach to the calipers. I replaced them with braided stainless steel lines to tighten

up the brake pedal feel that little extra bit. I bled the brakes using an el-cheapo one man brake bleeder

that seemed to work okay, but there's still a little air in the lines so I'm going to pressure bleed them.

The next issue to tackle was the check engine light. My dad and I use the

Ross-Tech vag-com software to interface

with our Volkswagen ECUs, so I fired up the little orange laptop and took a look at which DTCs (Diagnostic

Trouble Codes) were active. Of course, being an A3 Volkswagen, it was: G40 (Camshaft Position Sensor, Implausible Signal).

In english, that means "someone didn't know how to do the timing on this vehicle". After a couple of attempts

at setting the valvetrain-to-crankshaft-to-intermediate timing, I got it right on the money and the ECU

was happy again (no more check engine light).

After clearing the DTCs (necessary to shut the check engine light off in this case), the "Readiness Codes"

also get reset. I could write a whole book on readiness codes, but they're basically a bunch of

TRUE/FALSE conditions that all OBD-II (1996 and newer) vehicles store in their ECU. They are all directly

related to emissions equipment on the vehicle (evaporative emissions system, catalytic converter, oxygen

sensors, etc) and all of them must be TRUE (or READY) in order for the vehicle to pass New Hampshire

state inspection. So at this point, all of my readiness codes were FALSE (NOT READY). There are a series of

procedures that can be performed to enable the readiness codes one-by-one (these procedures vary depending

on the vehicle), or it can be done by simply driving the car under all possible driving conditions for several days.

So what I found while trying to enable these codes on our new Golf is that a few of them were failing. After

a lot of hassle and troubleshooting, I found that the ECU is reporting a rich condition under some of the

"driving conditions" and that is keeping some of the readiness codes from being set. I suspect a spark issue based

on the car not starting a couple of times after it had rained, and poor throttle response under most

conditions (I think all of my cars have had ignition issues at one time or another).

Along the way, I also replaced the front struts and strut mounts, as well as the exhaust. For the exhaust

I went with a cat-back system from Neuspeed... yes, the stainless one. You've probably seen it - it looks

pretty hot on an A3 Golf, with those dual up-swept outlets. I opted for the version with two mufflers and

one resonator, just like the stock system. I didn't want this to be a loud car, but I didn't want it to

sound stock either. The sound, I must say, is impeccable. Very subdued, but deep and a little bit throaty at

the same time. It's the polar opposite of my obnoxious sounding little A2. On a related note, I was very

impressed with the quality of the Neuspeed system. The welds were top quality, and the over-axle pipe mated

to the front pipe using a flange rather than the usual slip-over connection. The clamp for joining the

front pipe to the catalytic converter was also top quality. The fit was superb, and it was a breeze to install.

So, all in all I'm feeling great about this little car. I'm really excited to get it through inspection and have

Claire (my wonderful wife) start driving it on a daily basis.

|

|

|

|

|

|

A1 parts for sale:

|

Item:

Item: Intake air pre-heat hose (from exhaust manifold shroud to air box), for Scirocco 2 (1982+)

Condition: New

$12

|

|

|

|

A2 parts for sale:

|

Item:

Item: GTI dual-round grille with inner lights, bulbs, and lower trim strip

Condition: Used, lower trim strip is weathered.

$35

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

Item:

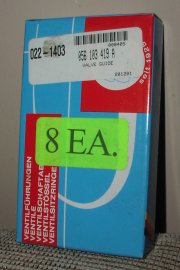

Item: 8 (eight) valve guides, German, standard size, for 8 valve head

Condition: New

$24

Item:

Item: Wheel cylinder (for rear drums, obviously), 2 available.

Condition: New

$12 ea.

|

|

|

|

A3 parts for sale:

|

Item:

Item: Parcel shelf strap, 3 available

Condition: New

$3.50 ea.

|

|

|

|

A4 parts for sale:

|

Item:

Item: OEM Water pump, ALH engines

Condition: Used, 130,000 miles

$20

|

|

|

|